TemperPack Raises $31MM From New and Existing Investors

As Home Deliveries Accelerate, TemperPack Expands Capacity

RICHMOND, Va., August 7, 2020 – TemperPack® Technologies, Inc., the lead manufacturer of sustainable thermal insulation for home deliveries of perishable foods and temperature-sensitive medicines, announces today that it has secured new investments totaling $31.3 million as part of a Series C financing led by Grosvenor Food & AgTech, the UK-based food and agricultural investment arm of the Grosvenor Estate. This latest investment round also included follow on investments by existing shareholders Revolution Growth, Harbert Growth Partners, SJF Ventures, Arborview Capital, Tao Capital, Third Prime Capital, and Greenhouse Capital.

Learn more about our Series C in Crunchbase’s exclusive coverage.

TemperPack’s suite of thermal products includes our flagship curbside recyclable ClimaCell® box liners.

TemperPack has seen significant growth over the last 18 months, accelerated by stay-at-home orders which have made home deliveries of meal kits, produce, and prepared meals more mainstream. In addition to bringing on new customers such as Illumina and New England Biolabs, existing customers have increased their orders, and TemperPack has more than doubled the size of its workforce since the end of 2018.

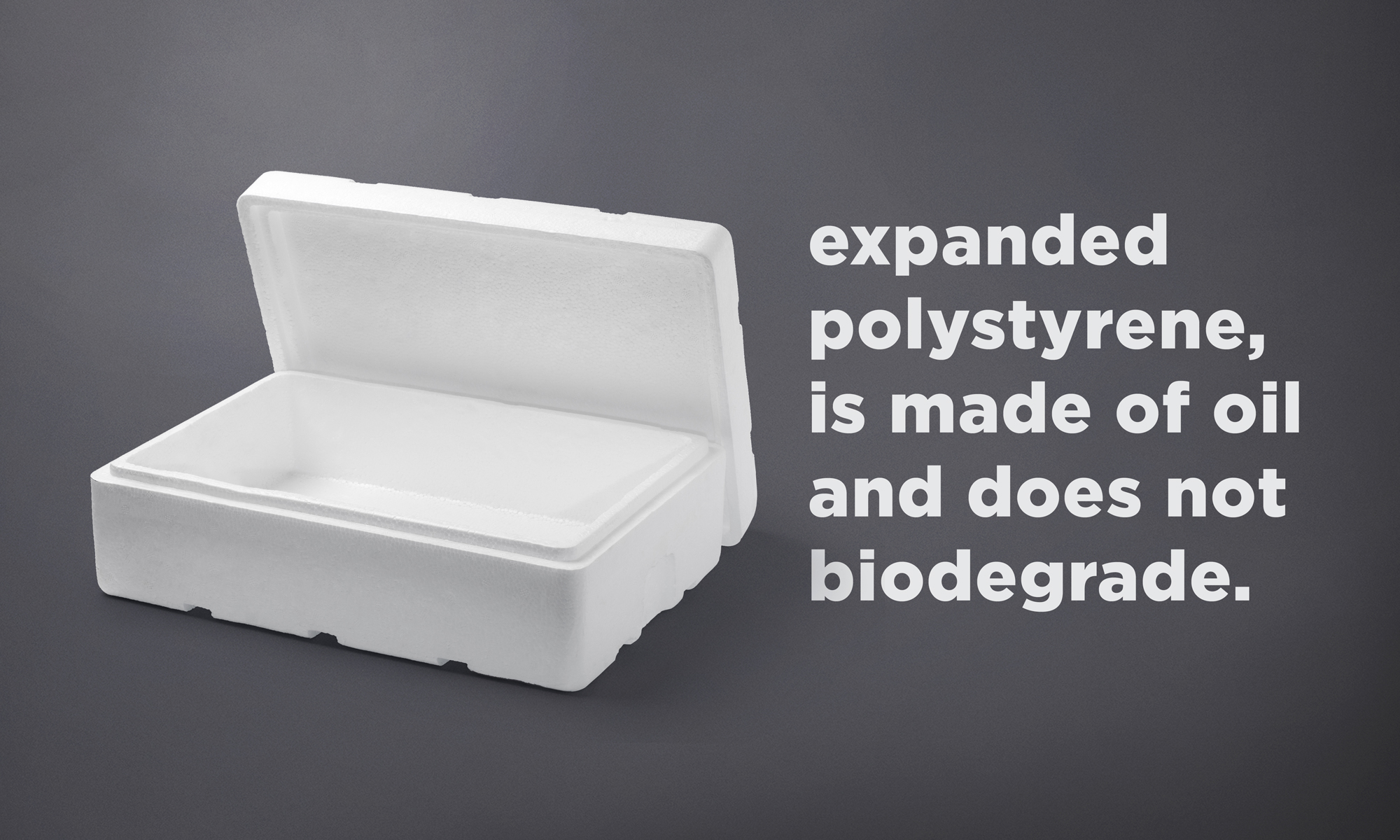

At the same time, life sciences companies shipping insulin, diagnostic tests kits, and biologic medicines are moving away from expanded polystyrene foam (EPS), also known as Styrofoam®. EPS has been banned by dozens of localities in the US for its harmful effects on the environment.

The new funding will enable TemperPack to expand manufacturing of its patented ClimaCell® thermal liners. ClimaCell liners provide similar levels of thermal protection as EPS. Unlike EPS, ClimaCell® is plant-based, 100% curbside recyclable, and reduces carbon emissions. The additional manufacturing capacity will enable ClimaCell to increase market share in the food and life sciences markets and positions TemperPack for future growth in new regions and applications.

" We’ve been seeing increased demand from companies across a range of categories in the food space and from leading life sciences companies proactively breaking away from Styrofoam. The time was right for us to look for partners to allow us to build and accelerate our growth. "

— Brian Powers, TemperPack CEO

“TemperPack is perfectly positioned for long-term growth thanks to a product that delivers a comparable performance to established alternatives but with the added benefit of being sustainable. There is significant opportunity within its core food and life sciences markets in the US and globally, and we expect the ClimaCell® technology will allow it to compete in other markets where Styrofoam is the incumbent material,” said Katrin Burt, Executive Director at Grosvenor Food & AgTech.

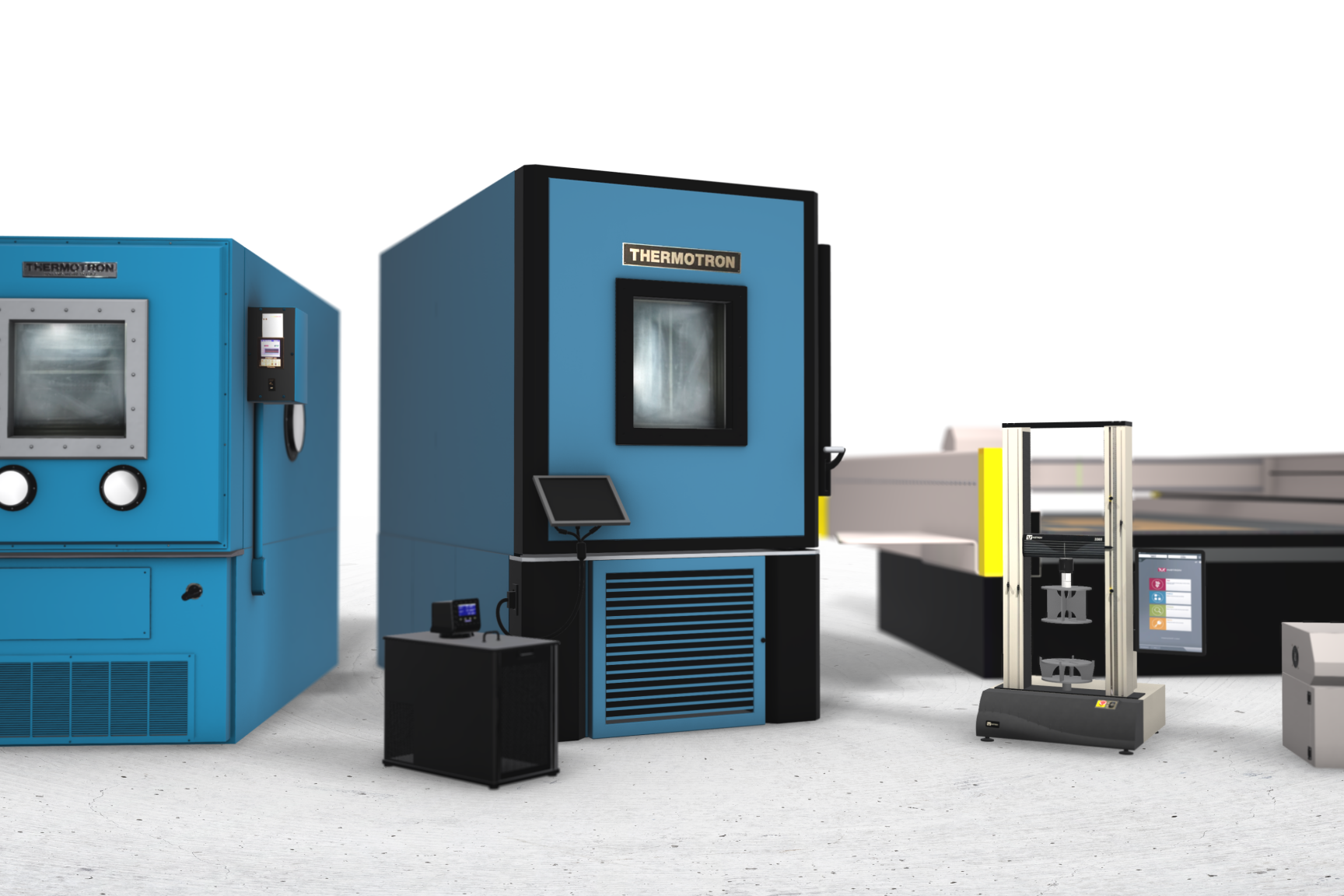

TemperPack is one of the only vertically integrated packaging companies to feature an in-house ISTA®-certified Thermal Transport Laboratory, available to all of our clients for qualified testing and solution design packaging.

With this round of funding, TemperPack has now raised over $78MM. The company has 200 employees and manufacturing facilities in Richmond, Virginia, and Las Vegas, Nevada. TemperPack estimates that, by choosing ClimaCell over EPS, its customers have avoided the creation of over 18 million kilograms of carbon missions and eliminated the need for over 220,000 cubic meters of plastic waste since 2018.

“The global pandemic swiftly accelerated the volume of home deliveries and will likely contribute to lasting changes in e-commerce behavior as well as increased interest in sustainability as trash bins overflow with non-recyclable shipping materials. We are proud to reinvest in TemperPack as they lead the movement from toxic, plastic packaging to sustainable alternatives,” said Todd Klein, Partner at Revolution Growth.

The company was founded in 2015 by CEO Brian Powers, Chief Product Officer James McGoff, and Chief Technology Officer Charles Vincent. TemperPack currently works with food delivery and healthcare companies including HelloFresh and Diplomat Specialty Pharmacy.

About TemperPack

TemperPack® makes packaging that works for businesses, people, and the planet. The company was borne out of a desire to reduce the amount of unsustainable packaging caused by the rise of e-commerce and perishable delivery. Incorporating environmental responsibility into product design, the company specializes in bringing the highest quality packaging solutions to scale. Operating an ISTA® certified Thermal Transport Lab and state-of-the-art production facilities in Richmond, VA and Las Vegas, NV, TemperPack is rapidly expanding its reach in the perishable food and life sciences industries with recyclable and compostable packaging solutions. Our mission is simple: protect products with packaging that protects the planet.

About Grosvenor Food & AgTech

Grosvenor Food & AgTech is an international investor in food and agriculture businesses.

Its focus is to rethink and re-shape how food is grown, produced, distributed and consumed, partnering with like-minded people to understand the complex interconnectedness of the agricultural ecosystem to manage its effects and enhance human health, the environment and enable producers to thrive.

Alongside Grosvenor’s other activities in international urban property, rural estate management and support for philanthropic initiatives, Grosvenor Food & AgTech shares in the organisation’s common purpose to deliver lasting commercial, social and environmental benefit – addressing today’s needs while taking responsibility for those of future generations.

Fast Company's 2020

World Changing Ideas Finalist

At TemperPack, our mission is simple: Protect products with packaging that protects the planet.

For the last five years, that mission propelled us to work hard to find a replacement for expanded polystyrene (EPS), also known as Styrofoam. EPS has a lot of attributes that make it a great packaging material in many applications, but it is hugely problematic for the environment, from cradle to grave. With the rise of e-commerce, we saw a huge potential surge in the use of Styrofoam to protect perishable foods and temperature-sensitive medicines, and we also saw a huge opportunity to offer something better.

ClimaCell has been recognized as a “World Changing Idea 2020” by Fast Company.

Today that “something better” is ClimaCell. It offers similar thermal protection as EPS at a similar cost, but uses renewable ingredients, requires significantly less energy to manufacture, and is curbside recyclable. To date, Climacell has protected over 10 million shipments for companies including HelloFresh, Misfits Market, and Diplomat Specialty Pharmacy.

To us, replacing EPS is an important mission and real opportunity for growth. We learned last week that Fast Company thinks ClimaCell is a World Changing Idea. That’s pretty awesome.

Specifically, ClimaCell was named a Finalist in the Food Category, alongside awesome companies including AKUA, InFarm, AeroFarms, and our good friends and partners at Imperfect Foods. The whole World Changing Ideas list is here. And this video showcases a few really inspiring ideas outside the food category, including a new innovation from Abbott Labs for babies with congenital heart defects, a new 3D printer that can build a house, and a new innovation giving people in developing countries access to eyeglasses.

It’s an inspiring list. We’re grateful to be a part of it, and ready to keep going.

A Call For Reduced Waste in the Era of Home Deliveries

In early March, states began issuing stay-at-home orders in response to COVID-19. Not surprisingly, home deliveries have gone through the roof, and recycling bins are overflowing with plastic packaging. Most people don’t realize when they toss a container with the chasing arrows in the recycling bin, it’s more than likely to end up in a landfill.

It’s a complex problem. And one that’s not high on our national priority list in the face of the pandemic. But the sharp increase in shipping and deliveries has made this issue more important now than ever. Non-recyclable plastics are contaminating our water and soil. The chemicals used to manufacture them are toxic. The world has been turned upside down by a virus, and this could be the world’s opportunity to turn climate change upside down, too.

This year, we’ve set a goal to eliminate 10 million pounds of plastic from entering US landfills.

Packaging manufacturers are challenged to find scalable technologies that provide a viable alternative to single-use plastics without compromising consumer preferences for affordability, brand appeal, and quality. Stuck with traditional technologies largely built around plastics, they promote recycling as the solution and increase their labeling efforts to communicate “proper disposal” to the consumer.

And yet there’s no point in collecting and sorting waste if you can’t find a buyer. Current viable markets in the U.S. only exist for typical water bottles and milk jugs. Consider all the other plastics that consumers use daily: coffee pods, fruit containers, plastic bags, wrappers, clamshell packaging, bubble wrap and air pillows, take-out containers, and the list goes on. According to National Geographic, 91 percent of plastic is not recycled and either becomes trash or litter. Recyclers are faced with outdated infrastructure and collapsing markets for the items that they are collecting, so they send it to the landfill. This information never reaches the mass consumer market so they continue to do what they think is best and throw plastics in the blue bin.

What if manufacturers weren’t allowed to use the “chasing arrows” symbol unless their products were truly recyclable? Going further, what if products that cause problems for recovery facilities had a "harmful if recycled" label?

— James McGoff, Co-Founder & CPO

Earlier this year, Greenpeace published a report detailing the state of U.S. recycling and concluded: “Companies must move beyond the outdated, failed approach of promoting recycling as the solution to excessive plastic waste and pollution. Furthermore, few U.S. cities have industrial composting facilities required to treat compostable plastics and many compost facility operators don’t want compostable plastics. We cannot recycle or compost our way out of the growing plastic pollution problem. Instead of pretending that the trillions of throwaway plastic items produced each year will be recycled or composted, we must stop producing so many of them in the first place.”

What if manufacturers weren’t allowed to use the “chasing arrows” symbol unless their products were truly recyclable? Going further, what if products that cause problems for recovery facilities had a “harmful if recycled” label? That won’t happen of course but I’d be curious to see how buying preferences would shift, and how big brands and retailers would react to this in terms of material selection. The question is not “how do we solve the challenges of recycling plastics?” or “when will the markets turn favorable?” It’s “how can we design products that are eco-friendly?”

Last year, we saved enough energy to charge 3.7 million cell phones for an entire year. This year we’re looking to double that.

Five years ago, we founded our company to offer a sustainable, plant-based alternative to Styrofoam, as only 3 percent of Material Recovery Facilities accept it and only 1.5 percent of the population has access to recycling it. The material itself is outdated, non-compostable, possibly carcinogenic, and is made from non-renewable resources in factories that produce heavy amounts of green-house gas equivalents. It’s also used all over the world in huge quantities.

The packaging and shipping materials we manufacture are one of several options available to companies who are truly committed to reducing waste. As businesses re-examine their environmental responsibilities, we must also increase public education so individuals understand the empty promise of the “chasing arrows” symbol. Until we decrease plastic production, local governments could create more industrial scale municipal composting sites and the federal government could explore stricter guidelines for when manufacturers can use the universal recycling symbol on their products.

Food and grocery deliveries will continue to increase as we shelter in place and it’s likely that many consumers will emerge from this period with an increased reliance on ordering online. The environmental consequence cannot be ignored. At the end of the day, we all want to fulfill our intention of recycling and contribute to a healthier planet.

2019 Environmental Impact Report

2019 Impact

Our mission is to protect products with packaging that protects the earth. 2019 was a great year for advancing this mission.

Our packaging protected over 19 million shipments in 2019. Since we were founded, that total is over 40 million. Last year, over 60 companies started using ClimaCell for thermal insulation, bringing our total customer count to over 100.

Those companies chose ClimaCell for its strong thermal performance, its potential to reduce overall shipping costs, the ingenuity and perseverance of our teams, and, of course its environmental sustainability.

We believe ClimaCell is the best performing, most environmentally friendly way to ship control room temperature (CRT), fresh, and frozen items.

Part 1

End of Life

Great product design starts with planning for what happens to it after it has served its purpose. We designed ClimaCell to be the first curbside recyclable high-performance thermal insulation, to keep waste out of landfills and give the raw materials another purpose.

Last year, by using ClimaCell instead of expanded polystyrene insulation (EPS), we estimate that our customers diverted over 3 million cubic feet of plastic foam out of landfills. That’s over 34 Olympic swimming pools.

Part 2

The Right Ingredients

We’re proud of our materials:

Our first product, Fiber, used re-purposed jute and cotton liners as the primary source of insulation. This gave second life to material that would have gone to the landfill.

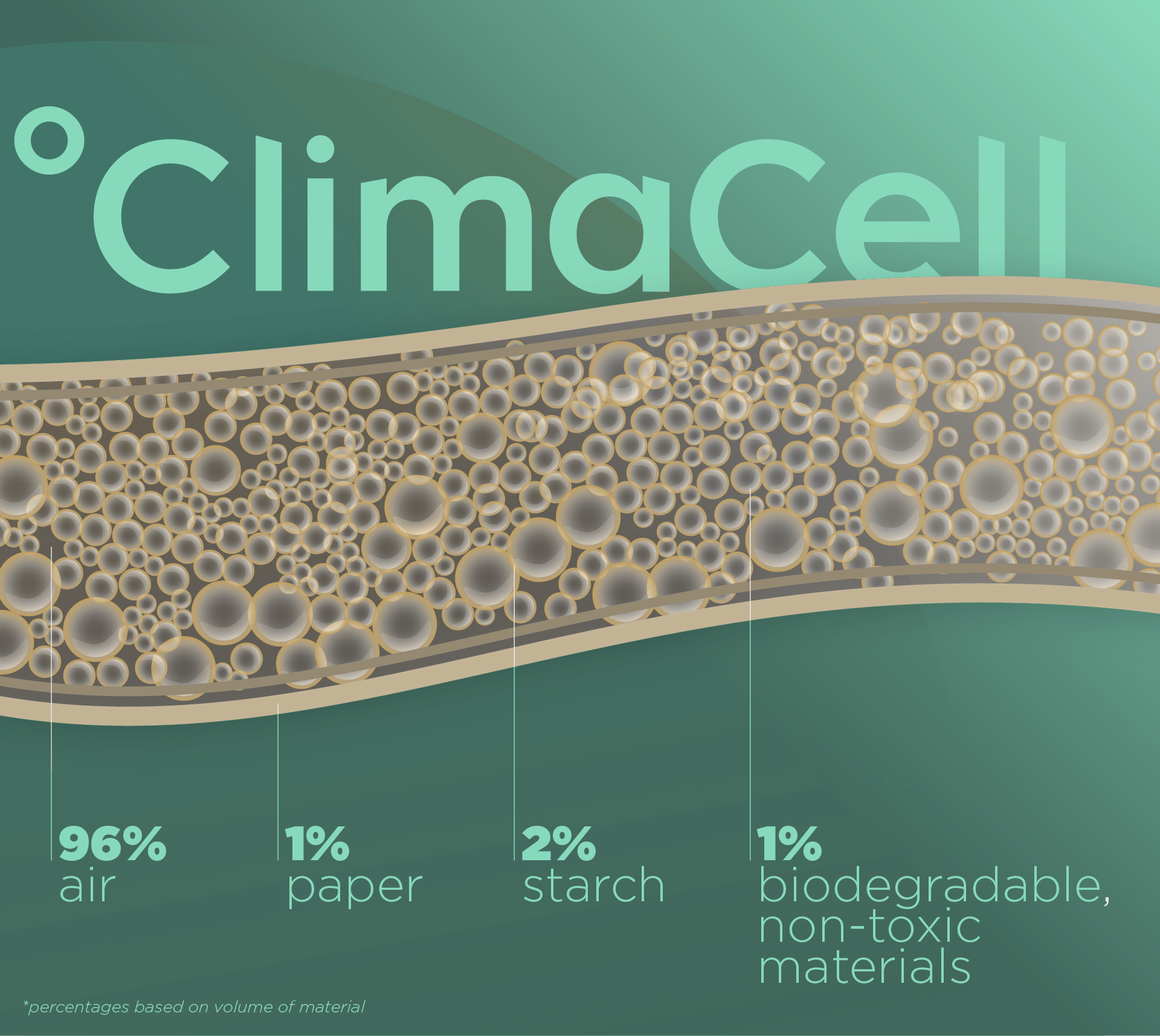

When we designed ClimaCell, we made a purposeful choice to start with renewable, plant-based materials. This is not only good for the environment but allows for traceability and assures our supply chain will be secure. By volume, ClimaCell is over 99% air, paper, and starch.

Part 3

Manufacturing Emissions

We developed a custom manufacturing process to maximize output with as much speed and as little energy as possible. This not only reduces our carbon footprint but also allows us to compete at scale with plastic materials.

This year, we reviewed our production output and our energy use in Richmond and Las Vegas, including our corporate offices, as well as data from:

- Dominion Energy

- Nevada Energy

- US Energy Information Administration

- Greenhouse Gas Protocol

- EcoInvent Database

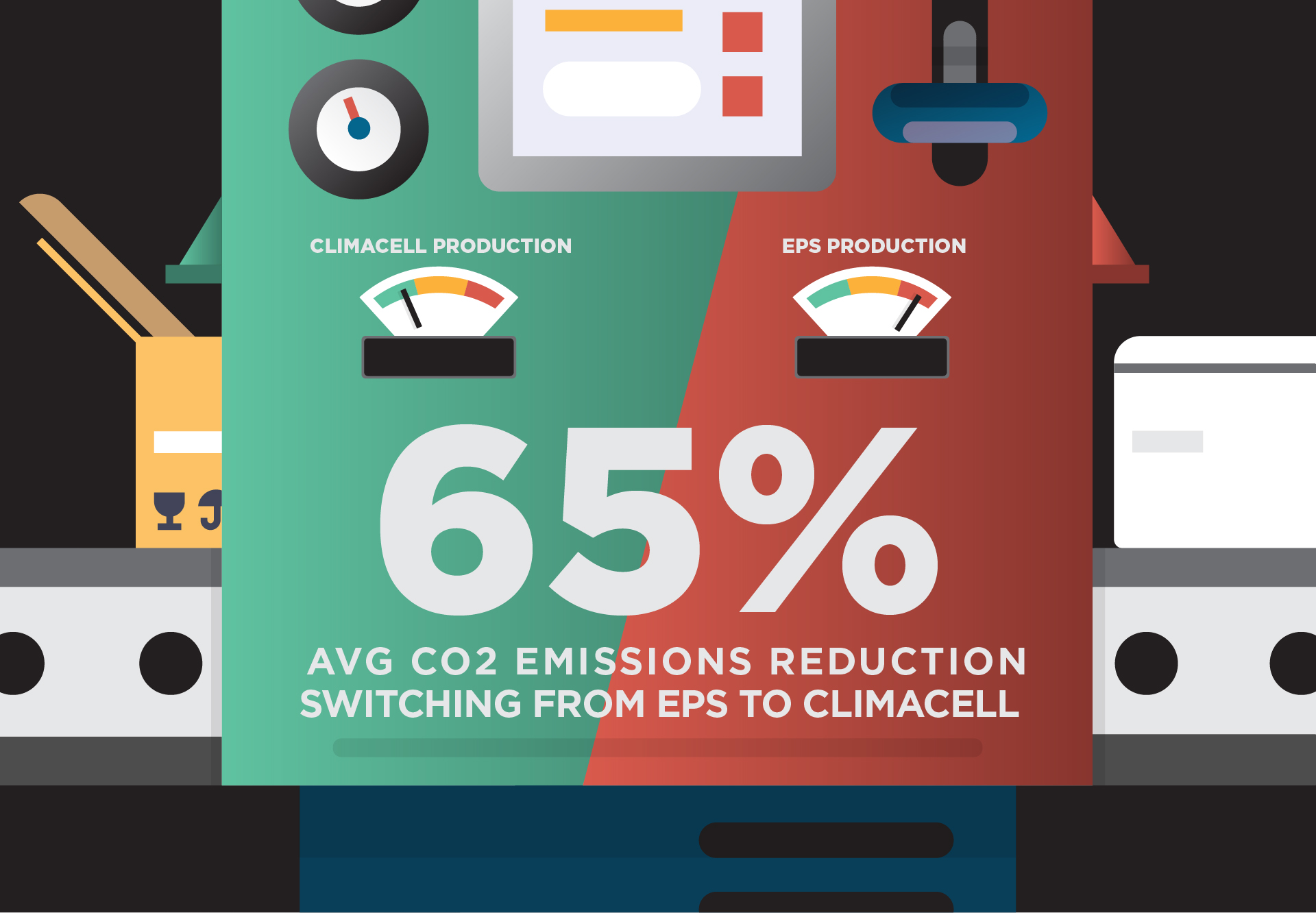

Using this data we were able to calculate estimates of the per-unit carbon dioxide emissions associated with manufacturing ClimaCell and of EPS.

Part 4

What does this mean?

In 2019, by using ClimaCell instead of EPS, we estimate that our customers avoided the creation of over 16,000,000 pounds of CO2 emissions. That’s like:

1,577

Cars removed from the road for one year.

120,667

Trees planted and let grow for 10 years.

2,547,945

Cell phones charged for an entire year.

277,232

Incandescent light bulbs switched to LED.

Work With Us

We’ve helped dozens of companies reduce their packaging costs and lower their overall impact on the environment. Give us a shout and we’ll work with you to develop a solution that suits your shipping needs.

How to Transition to Sustainable Thermal Packaging: A Primer

If your company makes or ships a product that needs to be kept cool, cold, frozen, or hot, thermal packaging plays a huge role in your future. This post contains the What, Why, and How of thermal packaging that sustains the planet and your business.

As our on-demand economy grows, whether you prepare fresh meal kits, frozen steaks, or ice cream, or develop cutting-edge biologic medicines, vaccines, reagents, there’s a good chance your customers want it delivered to their door, or will soon.

According to Nielsen, consumers will spend roughly $100 billion in online groceries by 2025.

Protecting those perishable shipments is the humble job of thermal packaging. This job used to be a dirty one, done by expanded polystyrene foam. If you don’t know what EPS is, it looks like this:

EPS does the job really well.

It’s inexpensive, but it’s plastic, cannot be recycled, and probably causes cancer, according to the World Health Organization. EPS also adds to landfills, where it might live forever.

This is a real problem.

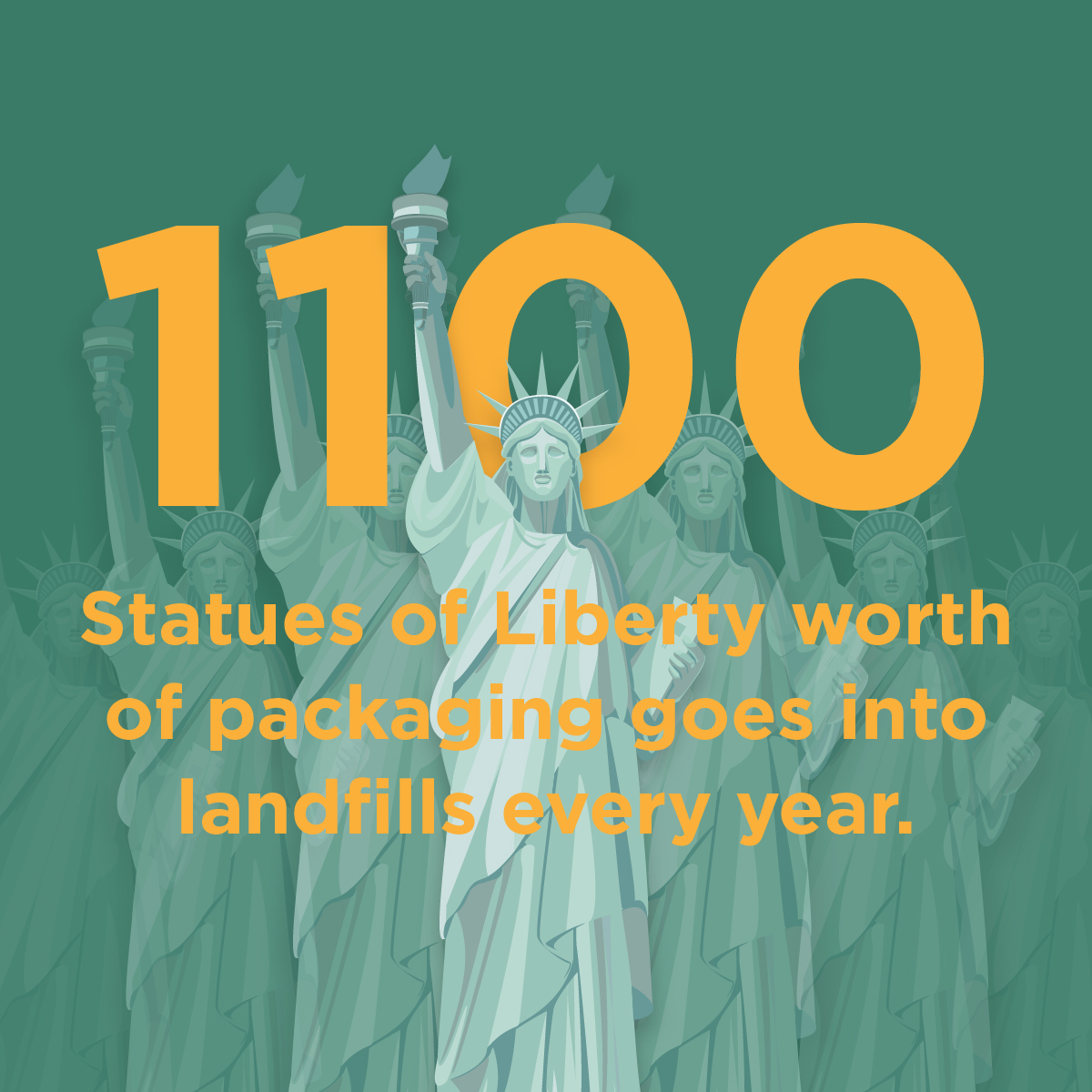

According to the EPA, containers and packaging account for 23% of the 150 million tons of waste that goes into landfills every year. That’s like 1,100 Statues of Liberty worth of packaging going into landfills every year!

But the good news is, more sustainable packaging is available today. These more sustainable options protect as well, can save you money, and are within reach.

In the next few sections, we’ll be talking about principles of sustainable packaging, thermal packaging basics, and how you can bring them together for a winning solution for your customers, the planet, and your business.

Part 1

What is Sustainable Packaging?

Sustainable packaging solutions are materials that take into account the entire life cycle of their usage.

Most packaging serves a single-use function and rarely takes into account where it will end up. Sustainable packaging can be a combination of different elements that reduce the carbon footprint, utilize rapidly-renewable inputs, and improve the lifecycle or reusability of the overall packaging.

There are many characteristics that impact how sustainable a packaging solution is. Here are a few:

Recyclable

Can be remanufactured into another product after use, unlike single-use plastics or synthetic foams.

Non-toxic

Does not release harmful chemicals or poisons into the earth.

Degradable

Will break down using natural forces such as air, light, and water, or chemical additives.

Compostable

Can be reused as rich a planting material even after the product’s original purpose is completed.

Many more factors exist in the sustainable packaging field, although these four are perhaps the most sought-after by Fortune 500 companies in the world today. Be sure to choose a factor or combination of factors that make the biggest impact on your company.

Part 2

Basic Principles Of Sustainable Packaging

As a general rule, the creation of sustainable packaging must adhere to certain guidelines under the protection of the Sustainable Packaging Coalition (SPC). The goal of the SPC is to help educate brand and business managers in government regulations regarding the proper distribution and management of sustainable packaging materials.

According to the SPC, there are four traits that packaging products should exhibit to be truly sustainable in every sense. These are:

Effective

Optimized in all aspects of its objective, and ultimately capable of being recovered and repurposed within an industry.

Efficient

Produces the highest amount of value possible. This includes saving time, money, and energy in the packaging process.

Cyclic

Can be reused or repurposed multiple times within its life cycle, mitigating the need for waste.

Safe

It is not only safe for consumer consumption but even healthful and beneficial as well.

It’s not easy to achieve all of these goals, even for relatively simple packaging solutions. Given the low cost of conventional single-use plastic packaging, even companies with the best intentions rarely get an A+ on each of those four metrics.

Reaching these sustainability goals is much more complicated when we’re talking about the much more complex challenge of thermal packaging.

Part 3

What is Thermal Packaging?

Thermal packaging is packaging that insulates a product against temperature change.

It includes any packaging solutions whose primary goal is to preserve, maintain, and otherwise insulate a product against heat or cold that could harm its integrity. In most cases, the enemy is heat.

Thermal packaging is particularly important to industries that require safe transit with little to no changes in product temperature. These commonly include chemicals or medications, foodstuffs, and plants or seeds.

Typically, thermal packaging requires three core components:

Coolant

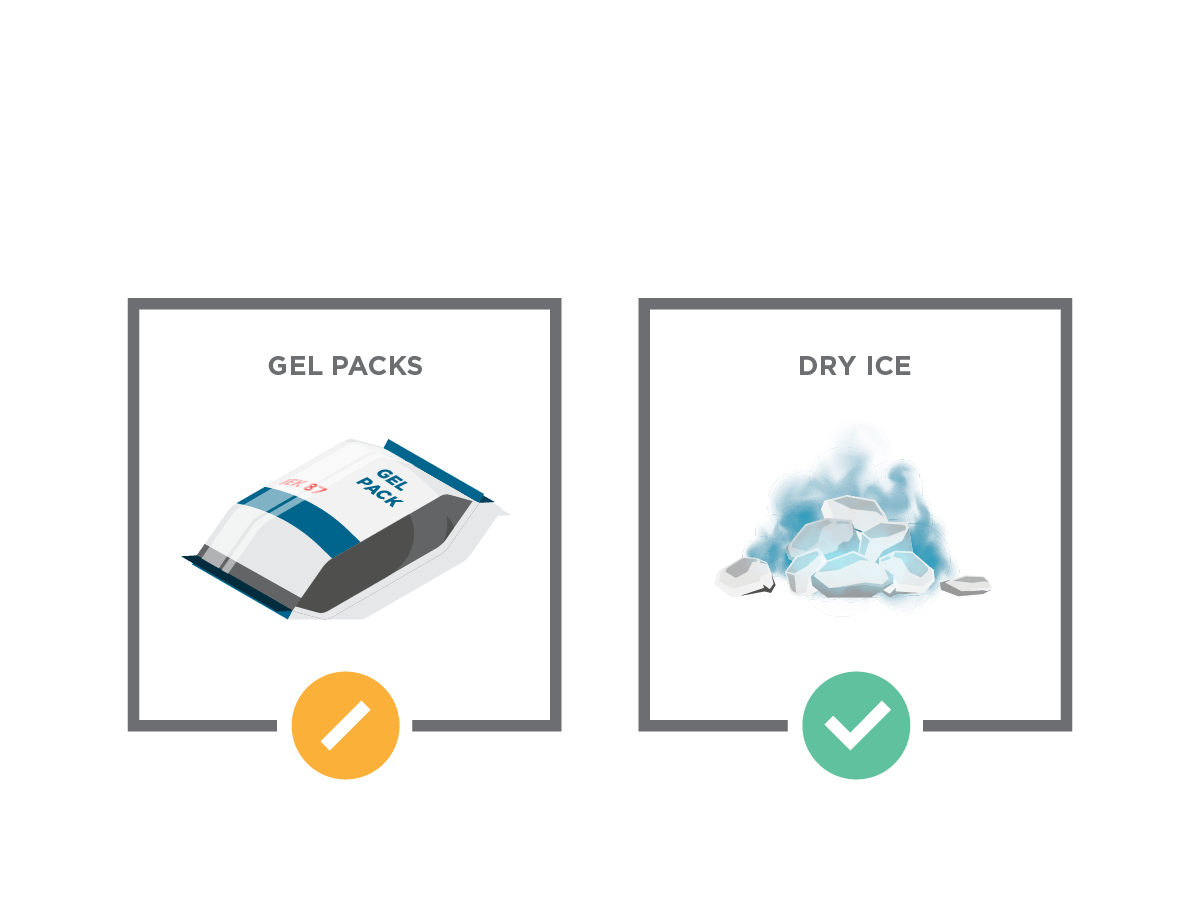

Coolants are components that actively create temperature change. The most common ones include ice, gel packs, dry ice.

- Dry ice is extremely cold, frozen carbon and dissipates over time, leaving nothing behind to dispose of.

- Gel packs are frozen liquid inside of a bag or container. Some are drain-safe, others need to be thrown away, some are even made of plant fertilizer and maybe once again returned to the earth.

Gel packs are good coolant, but they are traditionally wrapped in unrecyclable plastic. Dry ice is a great coolant that disappears after usage.

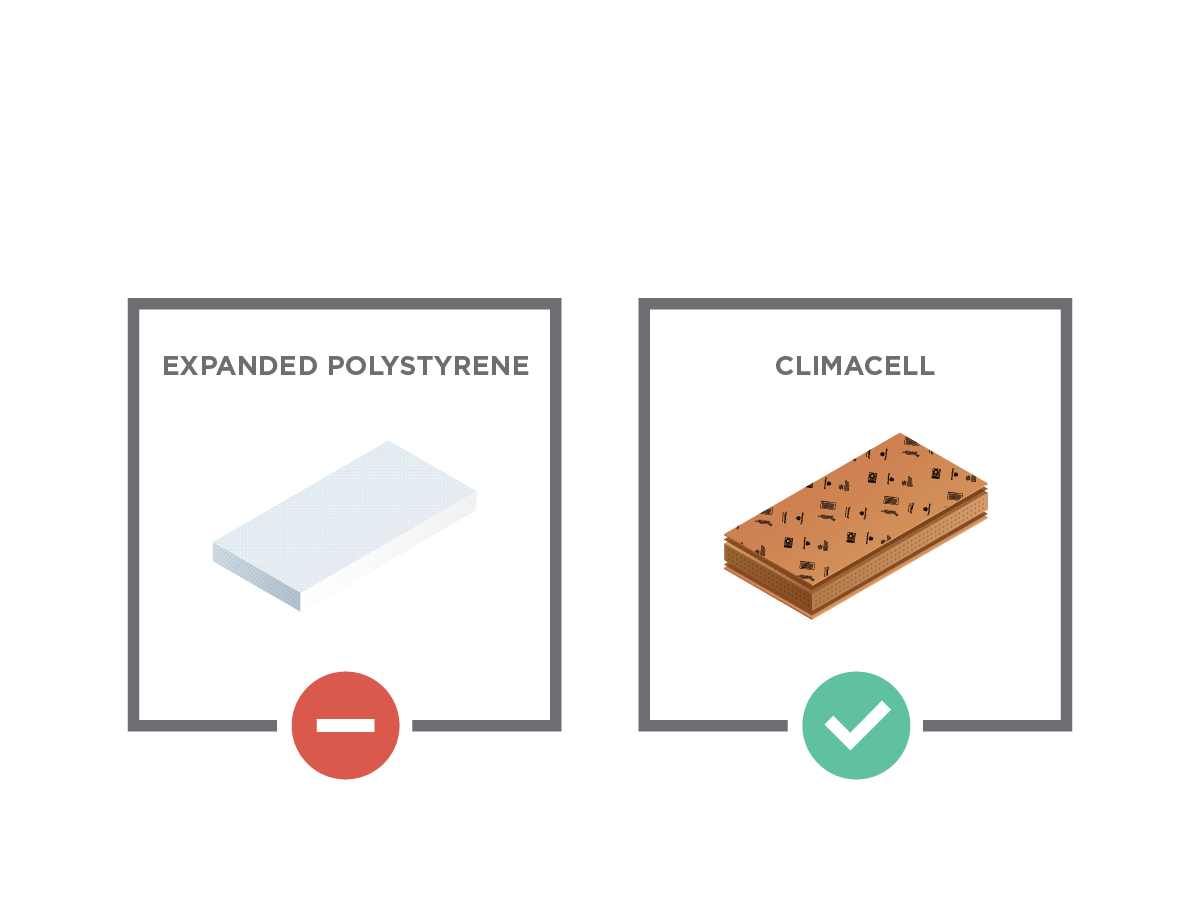

EPS is an old and effective insulator, but is extremely bad for the environment, both in its manufacturing process and end of life. New insulators like ClimaCell perform as well as EPS and are fully curbside recyclable.

Insulation

Insulation is material that doesn’t allow air (and therefore heat) to transfer. It keeps the cold in, even when it’s very hot outside.

- Expanded Polystyrene (EPS), better known as Styrofoam, is the most widely-used insulation. It’s effective as an insulator, but it’s an oil based plastic and is considered a likely carcinogen by the World Health Organization.

- Other materials have entered the market, including repurposed plant fiber, recycled PET, corn starch, and ClimaCell.

Shipping Container

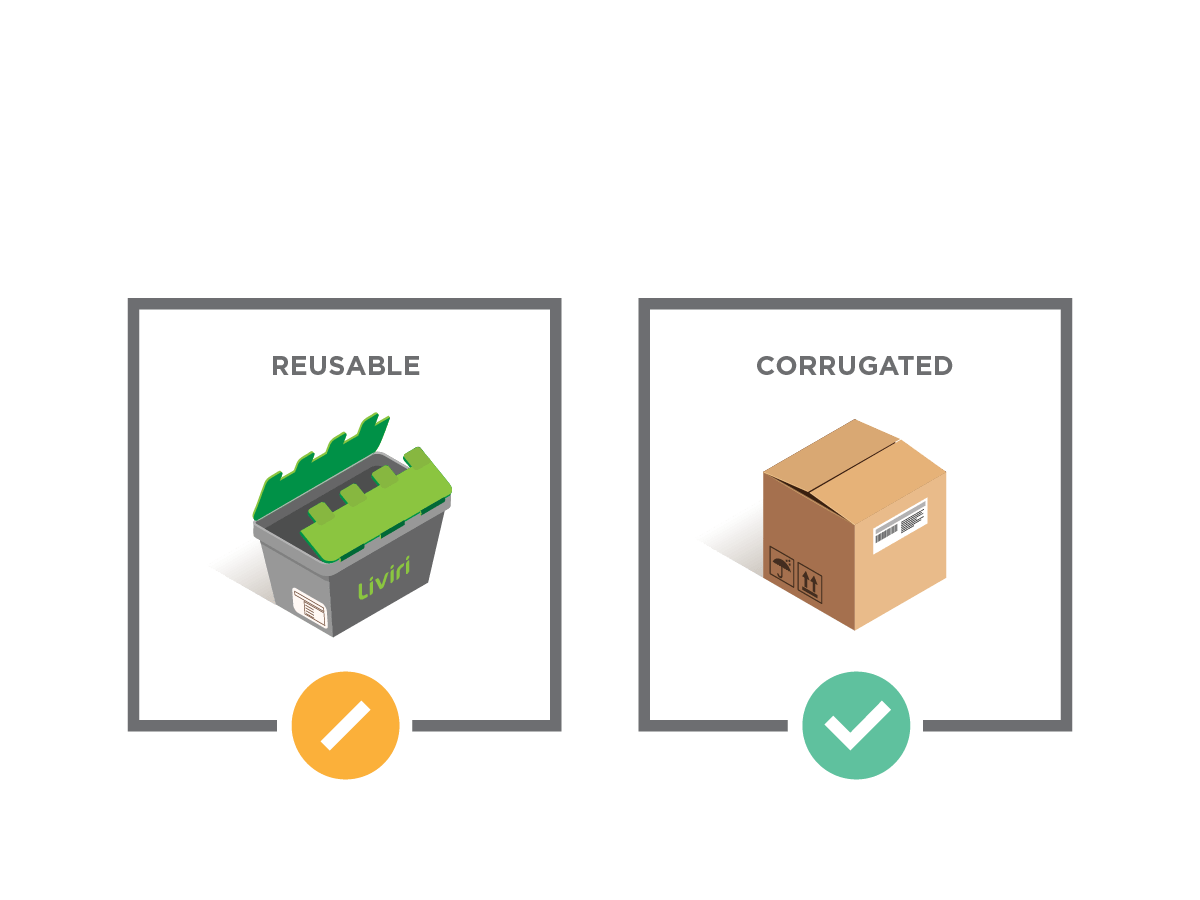

Shipping Containers are the outermost barrier of an insulated shipper - typically a corrugated box.

- These are typically the most sustainable part of the solution, since they are plant-based and curbside recyclable.

- Corrugated boxes are the most widely-recycled material in the country. They are recycled correctly 92% of the time, according to the EPA.

There has been a lot of press about reusable packaging. While the benefits are great for these types of shipping containers, their practicality in real-life situations is bad. Many of these containers are built stronger than necessary and never see the lifespan they were originally intended for.

The good news is, recent years have brought innovation to both coolants and insulation, to put more sustainable packaging within reach.

At TemperPack, we’ve focused on insulation, with ClimaCell being our latest innovation, and we believe the most complete thermal insulation on the market:

- Delivers high thermal performance similar to that of EPS, with comparable R-Values at equal thicknesses.

- Highly customizable material allows packouts to be designed to minimize DIM weights and shipping costs.

- Ships in flat panels for more efficient warehouse and truck space use.

- Semi-rigid, weight bearing material which can be easily folded and assembled in the fulfillment center.

- Made using plant-based inputs.

- Low-energy manufacturing process. Reduces CO2E emissions by 94% compared to manufacturing EPS.

- 100% curbside recyclable. The first curbside recyclable, thermal insulator to receive the “Widely Recyclable” designation from How2Recycle®, a program from the Sustainable Packaging Coalition.

Part 4

A Guide To Transitioning To Sustainable Thermal Packaging

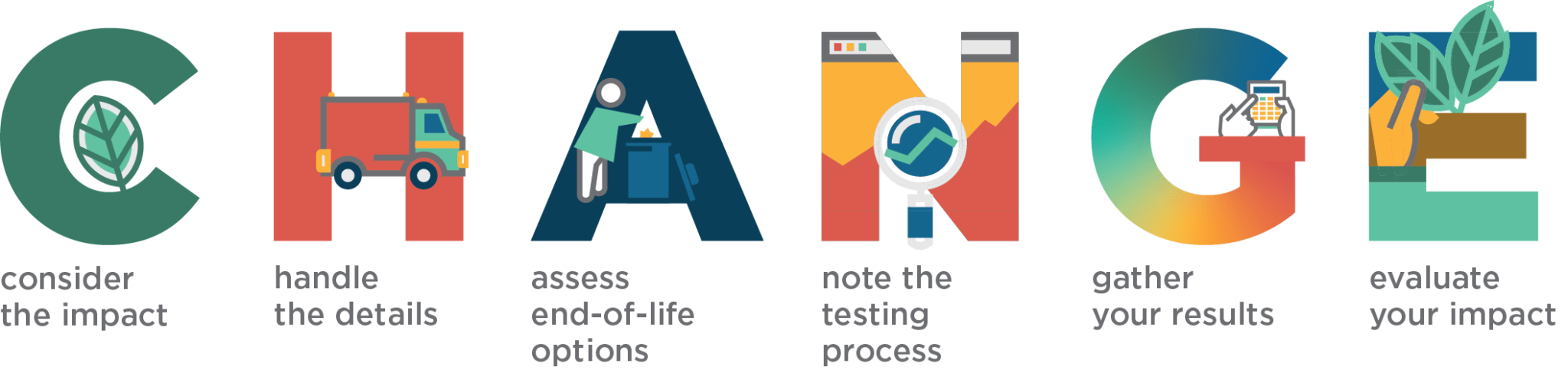

The process of transitioning to temperature-controlled sustainable packaging begins with CHANGE:

C - Consider The Impact

Take the time to assess the impact your choices will make on both your company and the future of your product. Will your eco-friendly packaging options maintain the three pillars of sustainability?

H - Handle The Details

Many minute details should be considered when switching to sustainable thermal packaging. Assess the temperature specifics, shipment climate, and time frame of your particular product or products. As always, TemperPack welcomes any conversations about sustainability details with our on-site innovation experts.

A - Assess End-Of-Life Options

One of the best parts of transitioning to temperature-controlled sustainable packaging is discovering the best possible end-of-life options for the material in question. Your packaging options are made further sustainable by including curbside recycling, composting, or biodegradable qualities that increase your impact on reducing the packaging footprint.

N - Note The Testing Process

Nothing about your decision to transfer to sustainable thermal packaging should be on a whim. TemperPack offers clients an innovative testing lab that can accurately predict the outcomes of your product paired with our packaging solutions, all without the sunk cost of valuable products.

This process has assisted dozens of industries during the initial planning stage, especially pharmaceutical companies, and related distributors.

G - Gather Your Results

Temperature-controlled sustainable packaging produces widespread and measurable results felt in every aspect of your business. Carefully measuring changes to your ROI, your consumer base, and the environment are great ways to visibly keep track of how your company may be combatting plastic pollution with sustainable bio-based packaging.

E - Evaluate Your Impact

Several industries are already benefiting from this type of packaging in major ways, especially pharmaceutical, life science, and food industry providers.

As companies begin to make the necessary changes and leap into the sustainable packaging industry, TemperPack is proud to offer comprehensive and affordable solutions within this growing industry of packaging and beyond.

Part 5

How Will You Benefit From Transitioning To Sustainable Thermal Packaging?

The benefits included with transitioning from single-use packaging to sustainable thermal solutions go far beyond reducing your carbon footprint. Making the switch to eco-friendly sources will affect your entire production system from development to manufacturing to shipment.

Consumers want it.

Many surveys show consumers want sustainability, and a new study shows they mean it: 50% of the growth in CPG products came from brands with sustainability claims.

Regulation is coming.

EPS has been banned in Maine and several major localities. Switching to plant-based, recyclable packaging now eliminates this risk to your business.

It's better for the planet.

Manufacturing ClimaCell reduces carbon emissions by 94% compared to EPS.

You can reduce costs.

Many renewable materials like ClimaCell are much more customizable for specific payloads and shipping requirements than EPS. This creates a real opportunity for a net gain in packaging and shipping spend.

We’re Here to Help.

Making the switch from traditional materials to sustainable and eco-friendly packaging is no longer a part of the distant future, but a current reality that companies must embrace to maintain a high ROI, nurture their stakeholder relevance and reduce their overall impact on our planet.

While it may not seem like an easy transition, sustainability in all aspects of your business begins with a commitment from you and all members of your company.

Reusable Packaging: Great Potential, But Challenges Ahead

Wouldn’t it be great if we didn’t have to throw so much packaging away? Reusable packaging feels like a huge step toward reducing what goes into landfills. We're excited to see great companies such as Nestle and UPS joining the TerraCycle Loop initiative. We also applaud Otter Products in exploring ways to make reusable packaging mainstream. All of this is not only exciting, but also imperative.

Unfortunately, the path to high-volume reusable packaging isn’t nearly as smooth as it may seem. Customer costs, logistics, and efficiency are just three of the main stumbling blocks for companies exploring reusable packaging.

Customer Costs

Although the meal-kit industry is likely to see strong double-digit growth year-over-year through 2023, customers switch services frequently. We can all agree the world needs less Styrofoam®, but customers may not be ready to pay for a deposit for a reusable package. Amazon and PeaPod have both struggled with this problem. These deposits increase customer acquisition costs and present a barrier to trial for companies that pass those costs on to their customers. In the future, if customer preferences have stabilized, companies might be able to charge for a reusable option. For now, this market segment is likely to remain volatile for the foreseeable future.

Logistics

The reverse logistics associated with collecting, sanitizing, and re-deploying packaging are costly and labor intensive. These reverse logistics tend to work only in closed-loop systems, such as blood banks. Meanwhile, people recycle corrugated paper properly 93% of the time. New forms of e-commerce packaging should be designed to leverage the existing efficient, nationally available, corrugated waste collection streams. Reusing a single package hundreds or thousands of times may be more environmentally sustainable than using responsibly-designed single-use packaging solutions. The question remains: "will people actually re-use these packages, and is the energy required to make this system work worth it?"

Efficiency

Right now, meal-kit services are focusing on fundamentally proving the viability of their business models. They are taking a hard look at their cost structures, with packaging and logistics front and center. It's much easier to continuously customize single-use packaging, using various pack-outs, sizes, and components to minimize footprint, cost, and weight. Reusable systems are less efficient because they are expensive and hard to change once the investment has been made. Reusable packaging is rigid in a market that still very much relies on a flexible supply chain. We're happy to see innovation in the space of e-commerce and subscription-based cold-chain packaging. At this point, however, the market cannot bear the costs or complexities of implementing reusable packaging.

As work remains to be done with reusable packaging we will continue to innovate and create more in the world of temperature stable, paper-based, curbside recyclable products. In the end, reusable or recyclable, we can all do well by creating better solutions for the planet.

The Atlantic's Article on Recycling is a Missed Opportunity

Alana Semuels’ recent article, "Is this the End of Recycling?" in The Atlantic seems to have re-ignited conversations about the business and habits of recycling in the U.S. Here’s the good, bad and ugly about the author’s take on the state of recycling in our union.

in The Atlantic seems to have re-ignited conversations about the business and habits of recycling in the U.S. Here’s the good, bad and ugly about the author’s take on the state of recycling in our union.

The Good – Semuels describes the financial impact of moving waste to landfills within the United States. I’m so glad she brought this up – she’s right, there is a real financial impact of moving waste to landfills across the country. I wish she would have explored this area further. The waste market should operate just like any other free market where behavior and price are intertwined. As recycling slows down, prices for landfilling will go up, cities will require a heavier tax for waste disposal to cover their increased costs from the waste management service providers. As this cost becomes front and center, consumers will become more cognizant of the waste they create, and as a result - will put more pressure on companies to build more sustainable products. The financial cost is nothing to hide from - it's the innovation driver.

The Bad – The writer doesn't come across as sympathetic to China's decision to place restrictions on imports of certain recyclables. The market for waste is like any other market. If you sell a bad product, you're going to get called out for it. The U.S. has been selling a bad product. China called us out for it in their notification to the WTO in 2017: "We found that large amounts of dirty wastes or even hazardous wastes are mixed in the solid waste that can be used as raw materials. This polluted China's environment seriously." - Ministry of Environmental Protection. If the roles had been reversed, the U.S. would have done the same thing (only sooner).

The Ugly – By “ugly” I mean confusing. The topic of recycling is actually fairly complex so when The Atlantic publishes an article that makes statements about organic waste in landfills, decomposing, emitting methane and its resulting impact on our environment, it's true but confusing. The article is about recycling and you cannot recycle many organic materials (e.g., tea bags, coffee filters, yard waste, not to mention the 3.5 billion lb. of food waste that we generate in the US each year), so those methane emissions seem odd to mention. Organic material should be composted (which was not even mentioned). This also seems odd to mention because plastics that are sequestered in a landfill do not generate emissions.

I admire Ms. Semuels for taking on the subject but she missed an opportunity to inspire leadership on a corporate and government level. We need to be less aspirational as consumers who believe we’re doing the right thing by throwing stuff in a green or blue bin and more geared towards risk/reward. In an ideal world, companies will make smarter choices about the materials they are bringing into their world, consumers will make better choices about how they dispose, and MRFs will invest into better sorting technology because China will be a happy customer wanting more. Right now, that's backward at every level because no one is really convinced (in their deepest self) that anything is at stake here. The problem isn't "real" enough yet.

James McGoff is the Cofounder and Co-CEO of TemperPack. Based in Richmond, VA, TemperPack seeks to solves the world’s packaging problems through sustainable deisgn.