TemperPack Closes Acquisition of KTM Industries, Inc.

TemperPack Closes Acquisition of KTM Industries, Inc.

Richmond, VA – September 6, 2022 – TemperPack® Technologies, Inc, a manufacturer of sustainable materials for cold chain packaging, announced that it has closed the acquisition of KTM Industries, Inc.

The acquisition was first announced on August 2nd, 2022.

KTM Industries is the maker of Green Cell Foam, a starch-based insulation material that is one of the protect perishable food and life science shipments. With this move, TemperPack will be able to offer customers an expanded product line and increased market coverage. The combined enterprise will have over 700 employees in four U.S. locations: Holt, MI, Las Vegas, NV, Reno, NV, and its headquarters in Richmond, VA.

“We’re thrilled to have completed the transaction and come together as one TemperPack. We’re excited to begin the process of working together to integrate our businesses and build on our strengths. Together, we are committed to bringing the market protective materials that are better for people and the planet.”

— Bob Beckler, Chairman and CEO

About TemperPack

TemperPack is the largest producer of sustainable cold chain materials for food and life sciences products in the U.S. The company’s mission is simple: protect products with materials that protect the planet. TemperPack was founded in 2015 to allow enterprises to ship perishable products without unnecessary plastic waste. Headquartered in Richmond, VA, with operations in Holt, MI, Las Vegas, NV, and Reno, NV, the company develops and scales innovative solutions that disrupt unsustainable packaging technologies. TemperPack’s products protect millions of shipments every month.

TemperPack Acquires KTM Industries, Inc.

TemperPack brings on Green Cell Foam, expanding its footprint in sustainable, protective materials

Richmond, Virginia (August 02, 2022) – TemperPack® Technologies, a manufacturer of high- performance, sustainable thermal insulation for cold chain packaging, announced today that the company has reached an agreement to acquire KTM Industries, subject to customary closing conditions. With this move, TemperPack will be able to offer customers an expanded product line and increased market coverage. Once the transaction is closed, the combined enterprise will have over 700 employees in four U.S. locations: Richmond, VA; Las Vegas, NV; Reno, NV; and Holt, MI.

The acquisition brings together two industry leaders in the development of renewable materials to compete with plastic foams and other harmful materials used in cold-chain and non-thermal, protective packaging. As TemperPack integrates teams, systems, and operations, it will leverage the capacity and expertise at each facility to offer customers the right solutions to meet their needs.

“We are exceptionally pleased to bring together these two companies with disruptive technologies and complementary, high-performance products including ClimaCell and Green Cell Foam to serve the rapidly growing need for sustainable, protective materials. The strategic fit of TemperPack and KTM could not be stronger. ”

— Bob Beckler, Chairman and CEO

Tim Colonnese, President and CEO of KTM, said “This is an exciting milestone for us, one that will create great opportunities to expand Green Cell Foam. We are fully aligned with the mission of TemperPack which is to provide engineered, protective materials that eliminate the need for synthetic foams which harm the environment. We are pleased to be joining forces with one of the most innovative and fast-growing companies in the industry.”

The transaction is expected to close in August, 2022.

About TemperPack

TemperPack is the largest producer of sustainable cold chain materials for food and life sciences products in the U.S. The company’s mission is simple: protect products with materials that protect the planet. TemperPack was founded in 2015 to allow enterprises to ship perishable products without unnecessary plastic waste. Headquartered in Richmond, VA, and with operations in Richmond and Las Vegas, Nevada, the company develops and scales innovative solutions that disrupt unsustainable packaging technologies. TemperPack’s products protect millions of shipments every month.

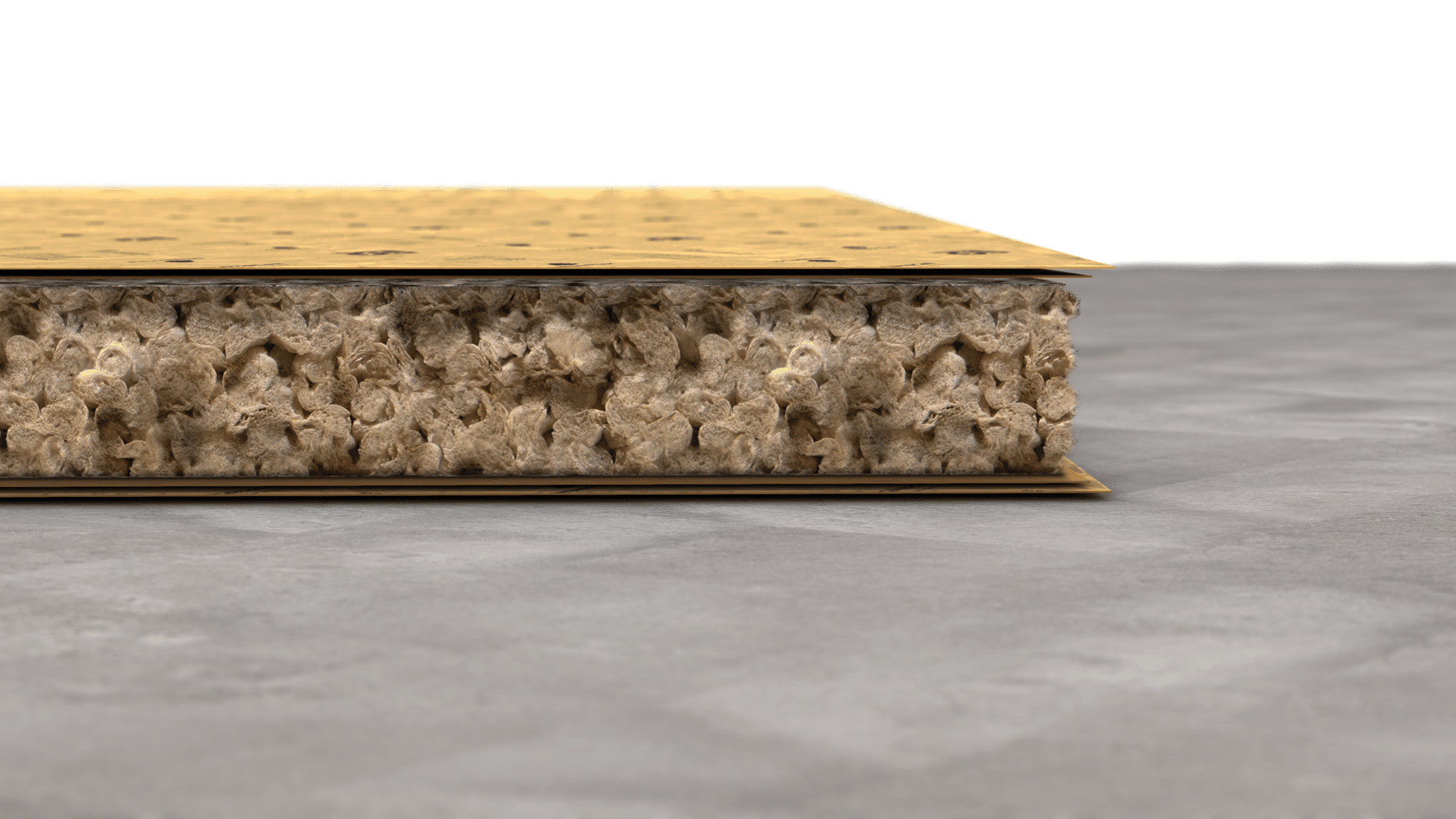

About KTM Industries

Green Cell Foam, a product of KTM Industries Inc., is a unique natural, environmentally friendly packaging material. Available since 2002, Green Cell Foam provides customers with an eco-conscious, compostable alternative made from cornstarch. The company provides design, testing and fabrication services at its Holt, Michigan and Reno, Nevada facilities. KTM has helped customers replace undesirable expanded polystyrene foam coolers in the pharmaceutical, specialty food and nutritional supplement industries, preventing over 10 million plastic-based coolers from filling landfills across the country.

2021 Impact Report

Helping companies reduce.

Our mission as a company is to protect products with materials that protect the Earth. When it comes to protecting the Earth, our primary focus has always been inventing new packaging solutions to displace single use plastic. But protecting the earth also means understanding our own impact, setting goals for reducing that impact, and sharing all that information with stakeholders. If you’ve made it to our website and are reading this, you’re a stakeholder. We welcome any feedback you have.

Metrics showing TemperPack’s 2021 environmental impact, plus the impact of ClimaCell compared to expanded polystyrene foam insulation.

Scope 1 Emissions

This is an estimate of emissions from our own facilities and assets, based on educated assumptions about the fuel used by vehicles we’ve leased and the Greenhouse Gas Protocol’s Transportation Fuel Tool. In our 2022 report, we will include any other direct emissions that come from other owned equipment (e.g. refrigeration, boilers, furnaces).

210MTCo2e

Scope 2 Emissions

Energy we purchased from Dominion Energy and Nevada Power for all three of our manufacturing and corporate facilities. Approximately 17% of that energy use came from renewable sources, including solar, wind, hydropower, geothermal, or nuclear.

2,602MTCo2e

Water Use

Water used in our Richmond manufacturing facilities. In our 2022 report, we hope to include our Las Vegas plant water usage.

14,746m³

Water Deep Dive

Fresh water is perhaps our most valuable resource. As part of our Life Cycle Assessment, which was audited by Long Trail Sustainability, we wanted to better understand our water use across the whole life cycle of our product.

1.27m³

Total water use in a typical ClimaCell solution, which includes the cardboard box and the packaging materials in which they are shipped to our customers:

Cardboard Box

ClimaCell Liner Material

Distribution Materials

Distribution

Electricity

Manufacturing

29,500

Comparing to EPS

By using ClimaCell instead of EPS, we avoided the creation of 29,500 MT of CO2e

Our ClimaCell® thermal liners were invented to be a curbside recyclable alternative to expanded polystyrene foam (EPS, Styrofoam®). When our customers choose ClimaCell over EPS, they prevent the release of toxins into the environment and keep waste out of landfills.

That's the same as...

6,357Cars

taken off the road for an entire year.

487K+ Trees

being planted and grown for 10 years.

3.5MM+ Smartphones

charged for a year.

1.1MM+ Light bulbs

changed from incandescent to LED.

13K

Pounds of waste diverted in 2021 using TerraCycle, N.O.P.E, and TFC recycling in our Richmond facilities.

Cleaning House, One Step at a Time

Minimizing waste sent to landfill is a motivation in our office, too. We’re launching a new partnership with CleanRiver, to help us develop a new waste station made out of recycled content that will help capture more of our waste and get it recycled. This upgrade in how we capture waste builds on existing relationships:

TerraCycle

for capturing difficult to recycle materials (wrappers, films) that normally require a trip to an off-side facility.

N.O.P.E. Compost

for capturing food and compostable packaging waste.

TFC Recycling

for capturing traditional paper, plastic, glass, and aluminum recycling.

2022 Goals for Environmental Impact ·

Scope 3 Emissions

We’re working to better understand our upstream and downstream impact to estimate and report our Scope 3 emissions.

Comparative LCA

We’re completing a 3rd-party verified, ISO compliant Life Cycle Assessment comparing ClimaCell to other materials.

Update on TemperPack’s impact in the areas of Safety, DEI, and community engagement.

Safety First

As a manufacturer, our #1 priority is Safety. We implemented additional safety training and awards in 2021 to deepen our focus on safety, and our Total Recordable Incident Rate (TRIR) improved 10% compared to 2020. That’s great, but our goal for TRIR is zero. That’s nearly unheard of in a manufacturing operation of our scale, but that remains our focus every day.

DEI

We want TemperPack to be a place where people feel they belong, are free to be themselves, and empowered to do their best work.

This year, our Diversity, Equity, and Inclusion (DEI) Task Force continued to promote inclusiveness in the company culture and track progress against our DEI priorities.

- We surveyed employees (anonymously) on their thoughts and perspectives on our efforts on diversity, equity, and inclusion; recommendations for improvements; and evaluation of our leadership’s focus on promoting opportunities for everyone at TemperPack, regardless of differences.

- We have specific, measurable diversity improvement goals that are reviewed by senior executives or our Board of Directors.

- We have created culture focused interview questions for all positions and partner with local groups that focus on hiring diverse candidates.

L.A.D.I.E.S.

Our Leadership And Development In Executing Success (L.A.D.I.E.S.) initiative, which is open to employees of all gender identities, continued with new programming to help employees develop and grow in their careers.

Community Outreach

We also created opportunities for employees to work together to help our community.

Capital Trail

TemperPack has adopted a segment of the Virginia Capital Trail, which employees volunteered to clean and remove litter.

Heart Walk

TemperPack participated in the 2021 Richmond Heart Walk to help fight cardiovascular disease here in the Commonwealth. The Heart Walk is the American Heart Association's premier event for raising funds to save lives from this country's No. 1 and No. 5 killers - heart disease and stroke. Our participation helped raise awareness and donations will help fund lifesaving breakthroughs.

Highlights capturing how engage stakeholders to improve our impact.

Task Force

TemperPack has a dedicated task force focused on ESG initiatives. This task force includes our Chief Executive Officer and collaborates with our Board of Directors to drive progress on ESG initiatives.

Customer Approval

out of 10 NPS Score

We try to solicit input from stakeholders across our ecosystem. This includes our customers, who received two surveys this year asking for input on what’s important to them and how we can be better. Our average response to the question “how likely are you to recommend TemperPack” was an 8.95 out of 10 across both surveys.

Employee Approval

We also surveyed employees about their experience at TemperPack, including giving the chance for employees to provide anonymous feedback on their manager or on other topics that they would like to raise.

We also conducted stay interviews with employees from varying levels of the organizational hierarchy about their experience at TemperPack. These discussions have initiated several improvements in the safety, training, and communication of our teams.

Strategic Partnerships

Lastly, we have purposefully surrounded ourselves with partners who help us stay informed and provide counsel when needed. In addition to our board, these include:

2022 Goal for Social and Governance Impact ·

Safety

Our first priority remains safety. Our safety goal is a TRIR of Zero.

Materiality

Develop and formalize a materiality assessment to shape our ESG strategy and reporting priorities going forward.

Reporting

Adopt a formal, widely recognized reporting methodology for our 2022 impact report

TemperPack Accelerates Growth with $140 Million in New Funding, Led by Goldman Sachs Asset Management

RICHMOND, Va., March 22, 2022 – TemperPack® Technologies, a leading manufacturer of sustainable thermal insulation for cold chain packaging, announced today that it has closed on $140 million of new equity financing, led by the Sustainable Investing business within Goldman Sachs Asset Management (Goldman Sachs). Goldman Sachs was joined by existing TemperPack investors including Grosvenor Food & AgTech, Harbert Growth Partners, Tao Capital Partners, Revolution Growth, SJF Ventures, and Arborview Capital.

TemperPack has experienced rapid growth in recent years, driven by strong demand for its patented ClimaCell® thermal liners. ClimaCell is the leading sustainable alternative to expanded polystyrene (EPS, Styrofoam®) for the shipment of perishable foods, pharmaceuticals, and other life science products. Unlike EPS, ClimaCell is non-toxic and curbside recyclable. The use of ClimaCell keeps plastic waste out of the environment and reduces carbon emissions.

The new funding led by Goldman Sachs will expand TemperPack’s capacity for protective materials technologies, grow its geographic footprint, and extend its customer reach.

ClimaCell® is the leading sustainable alternative solution to EPS coolers for shipping temperature-sensitive products. TemperPack produces millions of ClimaCell box liners every month out of their facilities in Richmond, Virginia and Las Vegas, Nevada.

" We are absolutely thrilled to partner with Goldman Sachs to accelerate our growth and diversify our offering of innovative, sustainable high-performance protective materials. As TemperPack grows, we increase the beneficial impact for consumers, our customers, and our planet. "

— Bob Beckler, Chairman and CEO

“Goldman Sachs is committed to partnering with outstanding businesses that help drive sustainability. TemperPack has demonstrated an ability to lead in the cold chain materials space with much-needed sustainable solutions. We’re excited to invest in TemperPack’s growth to accelerate the development of technologies that disrupt the use of conventional single-use plastics,” said Jeff Possick, Managing Director, Goldman Sachs Asset Management.

J.P. Morgan Securities LLC served as the exclusive placement agent for TemperPack in connection with the transaction.

About TemperPack

TemperPack is the largest producer of sustainable cold chain materials for food and life sciences products in the U.S. The company’s mission is simple: protect products with materials that protect the planet. TemperPack was founded in 2015 by James McGoff, Brian Powers, and Charles Vincent to allow enterprises to ship perishable products without unnecessary plastic waste. The company develops and scales innovative solutions that disrupt unsustainable packaging technologies, and its materials protect millions of shipments every month.

About Goldman Sachs Asset Management

Bringing together traditional and alternative investments, Goldman Sachs Asset Management provides clients around the world with a dedicated partnership and focus on long-term performance. As the primary investing area within Goldman Sachs (NYSE: GS), we deliver investment and advisory services for the world’s leading institutions, financial advisors and individuals, drawing from our deeply connected global network and tailored expert insights, across every region and market—overseeing more than $2 trillion in assets under supervision worldwide as of December 31, 2021. Driven by a passion for our clients’ performance, we seek to build long-term relationships based on conviction, sustainable outcomes, and shared success over time. Follow us on LinkedIn.

How to Ship Chocolates: Packaging Guide for E-Commerce Confectionaries

The Short of It

If you’re in the business of premium chocolate, whether you know it or not, you’re also in the business of thermal logistics. Getting your product to your customers’ homes in perfect condition requires a precise combination of insulation and coolant to prevent blooming, which occurs when chocolate gets too hot or too cold.

Want to learn more?

Read the full article below, or simply contact us.

Diving In

The US chocolate industry is expected to surpass $20 billion by 2025, with more and more companies entering the landscape. But as chocolatiers strive to grow, they’re realizing that success isn’t only based on creating the best product. It’s also about offering that product to their consumers where they want to buy it, which is increasingly online.

To build a strong e-commerce business for chocolates and confections, you need packaging that will stand up to the rigors of the supply chain and provide an at-home unboxing experience worthy of your premium brand.

Blooming is the enemy

Most chocolate wants to be 60-70°F. To delight your customers, you want your shipment to maintain that temperature range throughout its journey. When shipments get too hot or too cold, blooming happens.

Blooming is a term for the white, splotchy spotting appearing on chocolate that has been subject to improper fluctuations in temperature and moisture. With blooming, both visual appeal and texture can deteriorate.

There are two types of blooming: fat bloom and sugar bloom.

Fat Bloom

Fat bloom happens when the chocolate has melted and re-hardened due to temperature increases, which is typically beyond 80 to 90 degrees F, depending on the type of chocolate.

Sugar Bloom

Sugar bloom occurs when the chocolate is exposed to moisture, which can develop when the temperature drops too quickly to refrigerated temperatures.

Both types of blooming can spell doom for an overnight or two-day shipment, but they can be prevented. Here’s how:

Get the Insulation Right

The purpose of insulation is to slow down the transfer of energy from one space to another. Your choice of package insulation will have an impact on transit time, the amount of coolant you’ll need, and the size of box required.

Insulation will likely be your biggest packaging expense in your pack-out. There are many types of insulation materials available: expanded polystyrene foam, often known as Styrofoam®; cotton fiber liners; starch-based foam; bubble wrap; and recycled paper liners.

Here at TemperPack, we think our ClimaCell liners offer the best insulation on the market, especially for premium shipments. Our liners offer high levels of thermal performance and a sturdy structure for ease of use in your fulfillment facility.

Our insulation also uses kraft paper encapsulation, which creates an inviting unboxing experience for your customers at home. Paper signals quality, and people at home know it’s a more sustainable material than plastic. And ClimaCell liners are easily recyclable, so you’re not placing a burden on them to figure out what to do with the packaging you send them.

Be Smart About Coolant

In warmer climates or summer months, coolants can absorb the excess energy that is transferred from outside the box. In colder situations, coolants can expel that excess energy to maintain the optimal temperature for chocolate.

Coolant materials typically rely on their phase change to maintain a desired temperature. For example, water-based ice packs are a very effective material when trying to maintain temperatures close to 32 degrees F, the freezing point of water. However, water-based coolants are less effective when keeping temperatures that are much higher or lower than 32 degrees. PCMs, or phase change materials, are another possible high-performance option that can maintain temperature over a wider range of temperatures for longer durations.

Be Real about Your Primary Packaging

Primary packaging, which refers to the packaging materials used to directly contain your product, needs to match your brand experience, regardless of where it’s sold. When packaging chocolate for e-commerce purposes, it’s important to ensure that the primary packaging is sturdy enough to stand up to a shipment through trucks and warehouses. Sometimes the primary packaging you may use for retail might not be sturdy enough for the rigors of FedEx and UPS.

It’s also important to recognize that condensation is likely going to happen at some point in the shipment. If your primary packaging is built for presentation more than function, you might want to consider some kind of wrap in addition to the insulation to protect it.

Factor in Seasonality

As the seasons change, the amount of coolant and thickness of insulation can and should change as well.

It’s not just about melting: cold temperatures can have just as much of a negative impact on your chocolate as warm temperatures.

By staying in touch with conditions throughout your logistics chain, you can adjust your packaging accordingly to maintain quality. The right choices on your end will lead to a delicious experience for your customers.

Let's talk

Every company has its own unique specifications, based on their geographic footprint and preferred shipping criteria. Reach out or check out our lab page to learn more.

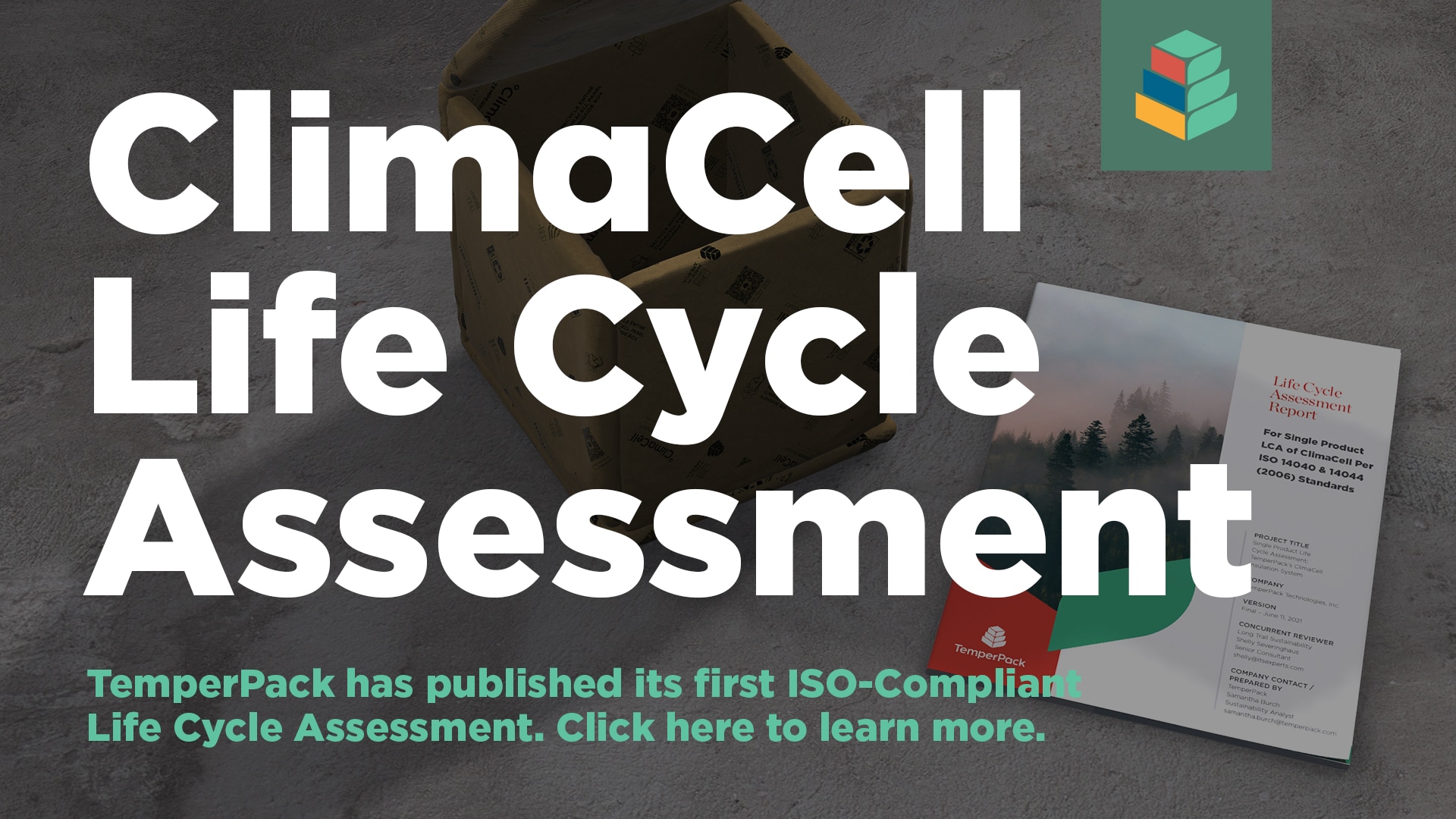

Our first ISO-Compliant Life Cycle Assessment

It's always been important to us to understand the impact of our packaging on the environment.

In our earlier years as a company, we made a good faith effort to estimate the impact of our ClimaCell thermal liners. We dove into data from utility companies, the U.S. Energy Information Agency, and available 3rd party databases such as the Greenhouse Gas Protocol. Our calculations in Excel were rigorous, but we knew we didn’t have the tools or expertise needed to produce an official ISO-compliant cradle-to-grave Life Cycle Assessment (LCA).

This year, that changed. TemperPack both obtained a SimaPro license and hired a sustainability analyst to build the single product LCA model and author the report. We also enlisted Long Trail Sustainability to conduct a concurrent critical review of both our model and report, in accordance with the 14040 and 14044 ISO standards (2006 a, b).

Why make this investment?

Well, according to co-founder and Chief Product Officer James McGoff, it was an easy decision. “Our company believes in doing the right thing, the right way, every time. One key step on that path is recognizing that data is king. Without it, it’s challenging (we’d go as far to say impossible) to assure continuous product improvement. We’ve long recognized the need to quantify the impacts of ClimaCell, and this year the time was right to take the next step to an ISO compliant model.”

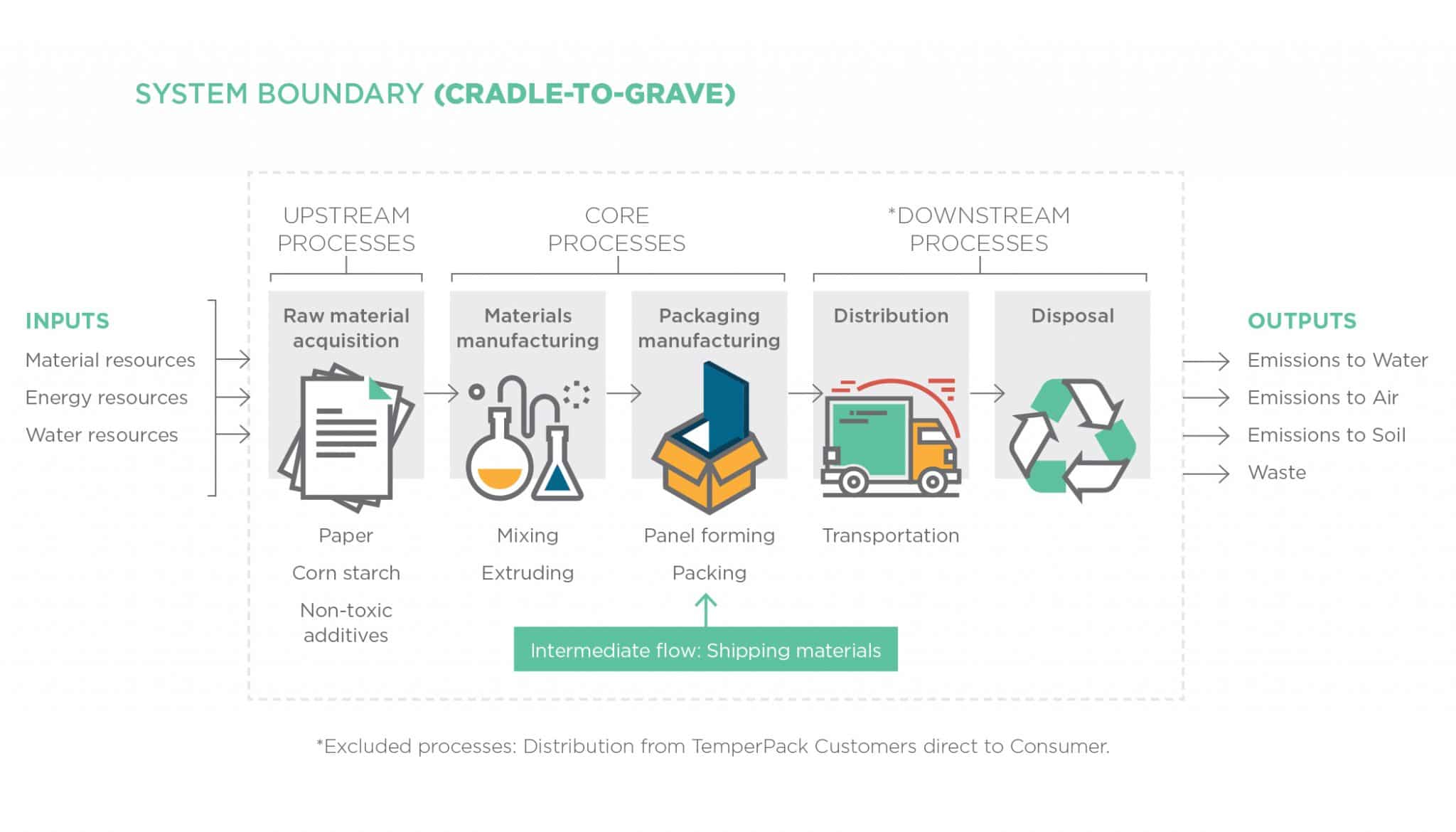

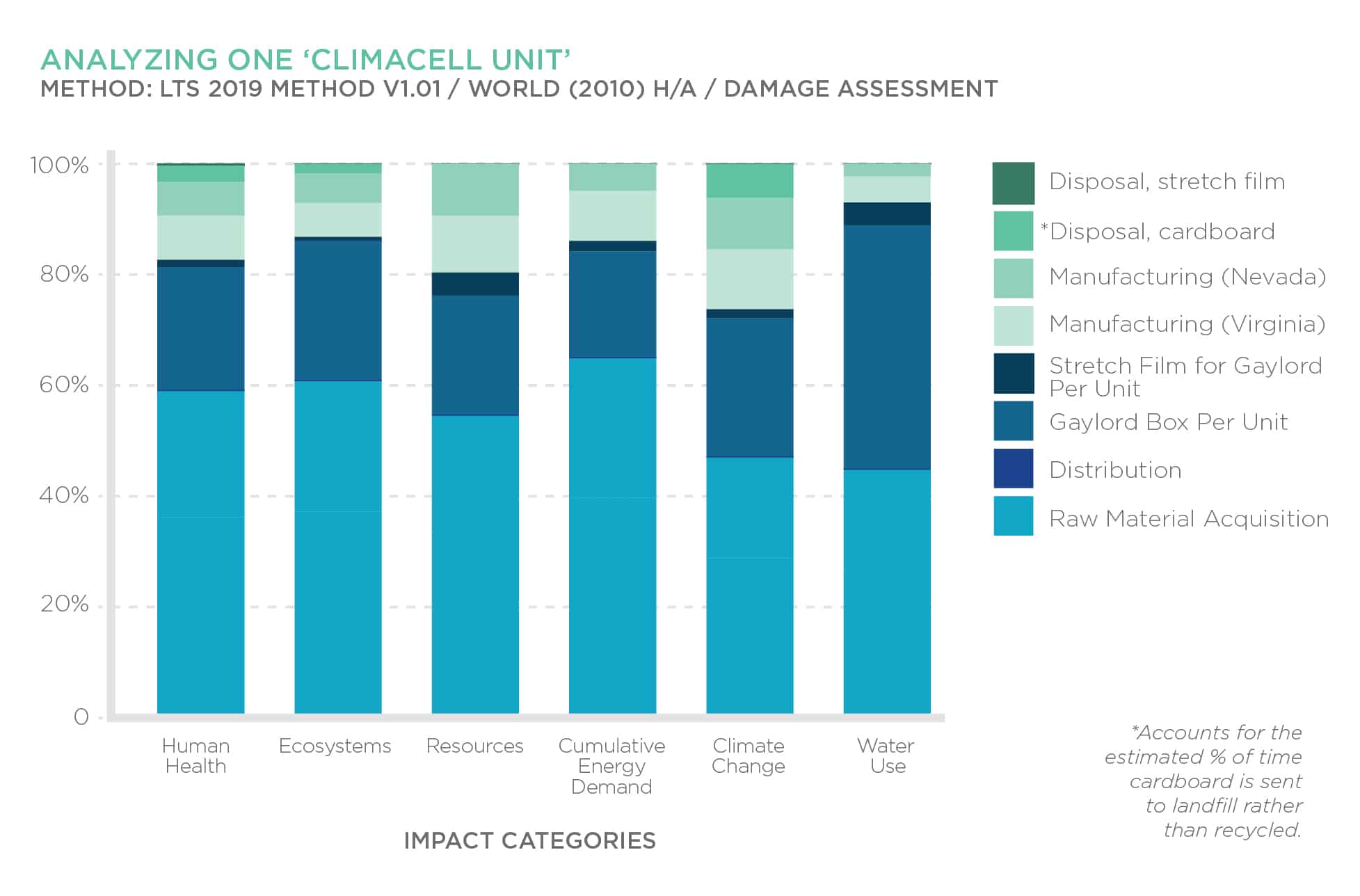

Below is a figure from the full report, demonstrating which processes within a ClimaCell Unit’s life cycle are included in the study:

The system boundary of this study reflects a cradle-to-grave study, encompassing upstream, core, and downstream processes.

Some of the findings?

Our Processes

Our upstream processes, which include raw material inputs and the distribution of those materials to TemperPack, account for almost 50% of the total GHG emissions associated with producing a single ClimaCell Unit. Meanwhile, the downstream processes, which include the distribution of a ClimaCell Unit to its customers and the unit’s disposal, account for about 6% of the total CO2e produced. Here is a more detailed breakdown:

- Upstream Processes (raw material acquisition) – 47%

- Core Processes (manufacturing) – 20%

- Intermediate Flow (materials used to distribute our packaging - gaylords, plastic wrap) - 27%

- Downstream Processes (distribution and disposal) - 6%

Our Materials

When assessing a single ClimaCell insulation liner, results also show that our corn starch-based packing peanuts generate the greatest environmental impact across all the mentioned impact categories.

Our Energy

Of all the environmental impact categories assessed (Climate Change, Human Health, Ecosystems, Resources, Cumulative Energy Demand, and Water Use), Cumulative Energy Demand accounts for approximately 56% of the total environmental impacts of a single ClimaCell unit.

This report is just one step in our journey of environmental stewardship. This model gives us a better grasp of the environmental hot spots of a ClimaCell liner across its lifespan. It also gives our customers better information and more confidence about our packaging. More importantly, it provides benchmarks and insights we can use to optimize ClimaCell and develop new products.

The TemperPack team is committed to smarter packaging for a sustainable future. This study is just one step of many on that journey.

If you have questions about our LCA, please reach out and we'd be happy to discuss it.

2020 Impact Report

2020 impacted all of us.

While the pandemic was the most important story of the past year, we will also remember 2020 as a year of unprecedented growth at TemperPack. As the world ground to a halt, we got to work, designing new products, manufacturing more SKUs than we've ever produced, and servicing the needs of our clients as they worked tirelessly to safely send food and medicine to people in their homes. We are grateful for all of our amazing partners. Below is a snapshot of the impact we made together last year.

2020 - Environment

With great less power, comes great responsibility.

With great less power, comes great responsibility.

We develop products to compete with traditional plastic insulation like expanded polystyrene. We design products with the goal to outperform those materials, but also to use less energy to produce and transport, and to be easily recycled instead of landfilled. This adds up to a better product, both for consumers and the Earth.

58MM+

Pounds of CO2

emissions avoided in 2020.

By choosing ClimaCell instead of EPS, our customers avoided the release of over 58 million pounds of CO2 equivalent emissions into the atmosphere.

97

Olympic swimming pools worth of plastic diverted from landfills in 2020.

By choosing ClimaCell instead of EPS, our customers replaced 97 Olympic swimming pools worth of unrecyclable plastic with material that could be easily recycled.

That all sounds great, but what does 58,753,193 lbs of CO2 actually represent?

1500

Cars

taken off the road for an entire year.

120K

Trees

planted and grown for 10 years.

2.5MM

Cell phones

charged for an entire year.

300K

Light bulbs

changed from incandescent to LED.

compared to similar

performing EPS products.

Water Reduction

Manufacturing is a resource-dependent activity.

Water we doing about it?

Our ClimaCell products reduce water consumption on a unit of output basis by 38% compared to EPS.

2020 - Social

Taking some initiative.

Despite the pandemic, in 2020 we’ve increased the number of environmental and social initiatives at TemperPack to be a more inclusive company and better steward of our own environment. These efforts represent our leadership’s dedication to creating a world that’s better for those living in it.

Expanding Partnerships

Building expertise in environmental issues, especially recycling, is essential to our success. That means working with great partners who lead the industry. This year, TemperPack joined both SWANA and ISRI. We’re participating in ISRI’s working group to draft a new Protocol for the Recycling of Paper Packaging. We also continue to work with the Sustainable Packaging Coalition and Closed Loop Partners. We have also engaged with independent paper mills and MRFs to introduce them to ClimaCell.

Virginia Capital Trail Sponsorship

We’ve sponsored mile 16-15 headed East, near the Sherwood Forest Plantation on the Virginia Capital Trail as another way to give back on behalf of the Pack. Our team has made efforts to remove trash along that mile five times in the past year.

Investing in Expertise

We’ve begun the journey to launch an ISO-compliant LCA for our ClimaCell product, expected to be published in the next quarter. The full study will provide our customers with even more clarity into the benefits and impacts of using ClimaCell. In the Fall of 2020, TemperPack took this first step in this process by hiring a Sustainability Analyst, whose role includes impact strategy, reporting, research, data analysis, and ESG program development.

Eliminating Waste

We’ve launched Sustainability Education trainings for employees that includes partnering with NOPE and installing TerraCycle Zero Waste Boxes to reduce waste from our facilities.

Public Recognition

In 2020, TemperPack was recognized by many for its environmental leadership. In November, TemperPack was featured in the Ellen MacArthur Foundation’s Upstream Innovation: a Guide to Packaging Solutions. Earlier in the year, TemperPack was named a finalist in Fast Company’s World Changing Ideas and in the SPC’s Protective Packaging Challenge.

Partnering with FeedMore

TemperPack became a member of Feed America and Meals on Wheels America — to collect, prepare, and distribute food to individuals in need. In Fall 2020, we volunteered 112 hours to support a program serving 20,000 meals each week.

Thought Leadership

We’ve dug into our own data and 3rd party research to create original content to show the need for sustainable packaging for the food and life science industries. UPS Healthcare posted this piece about the importance of thermal packaging in life sciences, and Closed Loop published our deep dive into meal kit packaging.

Stepping Up for Diversity

In October, the TemperPack Women’s Network established the Leadership And Development In Executing Success (L.A.D.I.E.S.) initiative to support and empower women at TemperPack through community outreach, webinars, and workshops. The group is inclusive of people of all gender identities.

TemperPack has also launched a Diversity, Equity, and Inclusion (DEI) Task Force to address current culture in the workplace, increase accountability, and identify new goals for corporate diversity.

Conclusion

Thank you for reading this update. We’re on a journey to be the best packaging company in the world. We want to create the highest performing, most environmentally friendly products, in a place where people like to work, can be themselves, and do the best work of their careers. We’re not there yet. While we work to get there, we want to hold ourselves to high standards and be as transparent as we can be.

Shoot for the moon and land there.

Thermal Testing Standards for Cold Chain Shipments: A Primer

For the vast majority of life-saving drugs, therapies, and vaccines, efficacy is inextricably tied to temperature stability.

The most common acceptable temperature range for cold chain pharmaceuticals is between 2°C and 8°C. Ensuring temperature stability across thousands of shipments as they move throughout dozens of distribution points requires precise, reliable testing.

The following is a look into how that testing is performed.

Thermal Shipping Regulation: Who’s Who

Effective transport of temperature sensitive products through the small parcel distribution network depends on guidance provided by multiple industry organizations.

The primary organization that provides guidance on the proper qualification of Insulated Shipping Containers (ISC) used for the distribution of temperature sensitive products is the International Safe Transit Association (ISTA).

The International Safe Transit Association, is an industry organization that provides standardized testing methods to members and provides lab certifications for both physical and thermal testing of packaged products.

The American Society for Testing Materials, is another organization with test standards that are used in the lSTA. While we focus more on ITSA in this article, ASTM covers a wide range of test standards and its test methods can be used for shipments destined for either domestic or international transit.

The Food and Drug Administration is the governing body that sets regulations for the proper certification of ISCs for drug manufacturers and distributors.

The Utilization Review Accreditation Commission, described as a “nonprofit accreditation entity”, oversees the validation process and requirements of ISCs used by specialty pharmacies in its 4.0 recommendations.

ISC

ISC is a packaging system as shipped. It typically includes an outer box, thermal insulation, coolant of some kind, and a temperature sensitive payload.

The Guidebook for Thermal Testing:

ISTA Standard 20

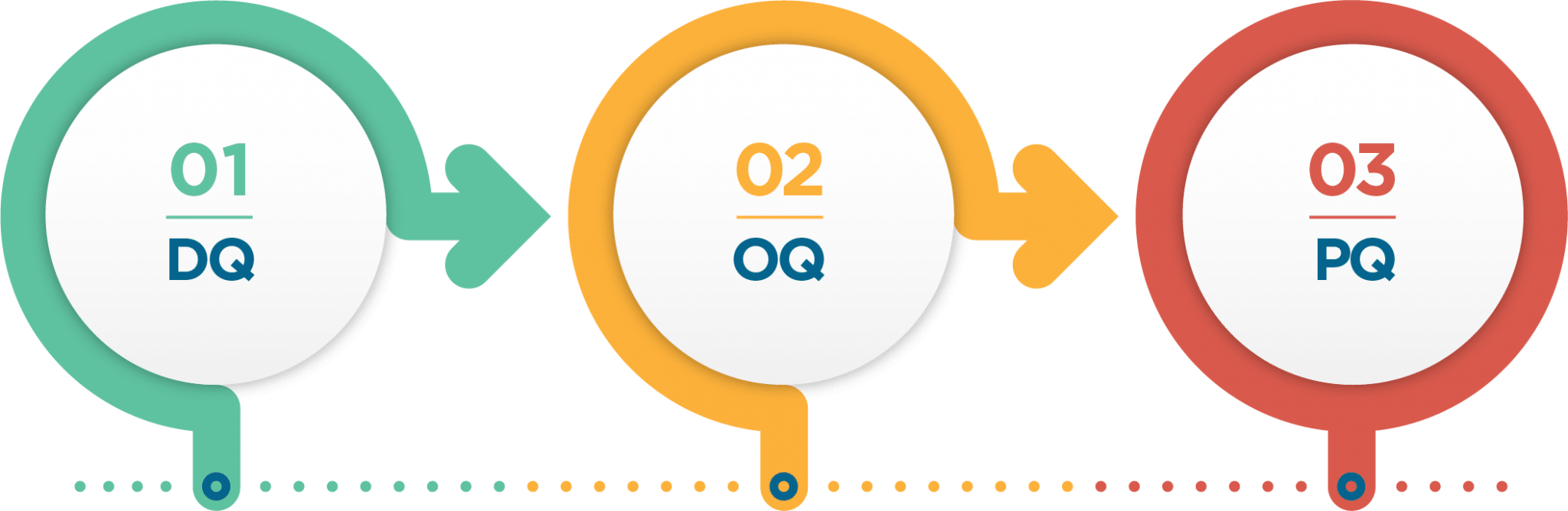

Due to a lack of standardization in the verification process of ISCs, ISTA established the ISTA Standard 20 (STD-0020), a testing process that outlines the process of design, testing, and verification of an ISC.

Proper execution of the Standard 20 process will certify that an ISC performs to the specified user requirements in a manner that meets FDA regulations. The Standard 20 process relies on three stages of testing to fully qualify an ISC.

STAGE 1: DQ

The initial stage is the Design Qualification (DQ), which is done either through environmental chamber testing or thermal simulation and only requires a sample size of one.

STAGE 2: OQ

After an ISC passes DQ, the Operational Qualification (OQ) is completed. OQ testing requires a minimum sample size of three and requires thermal chamber data as well as distribution testing.

STAGE 3: PQ

Following the completion of the OQ testing, the ISC is subjected to a Performance Qualification (PQ). The PQ is performed through real world shipments and requires a sample size of three shipments in the most extreme temperatures the intended season.

Standard 20 outlines the proper data collection process for each qualification step, as well as what to include in the final documentation for a fully qualified ISC.

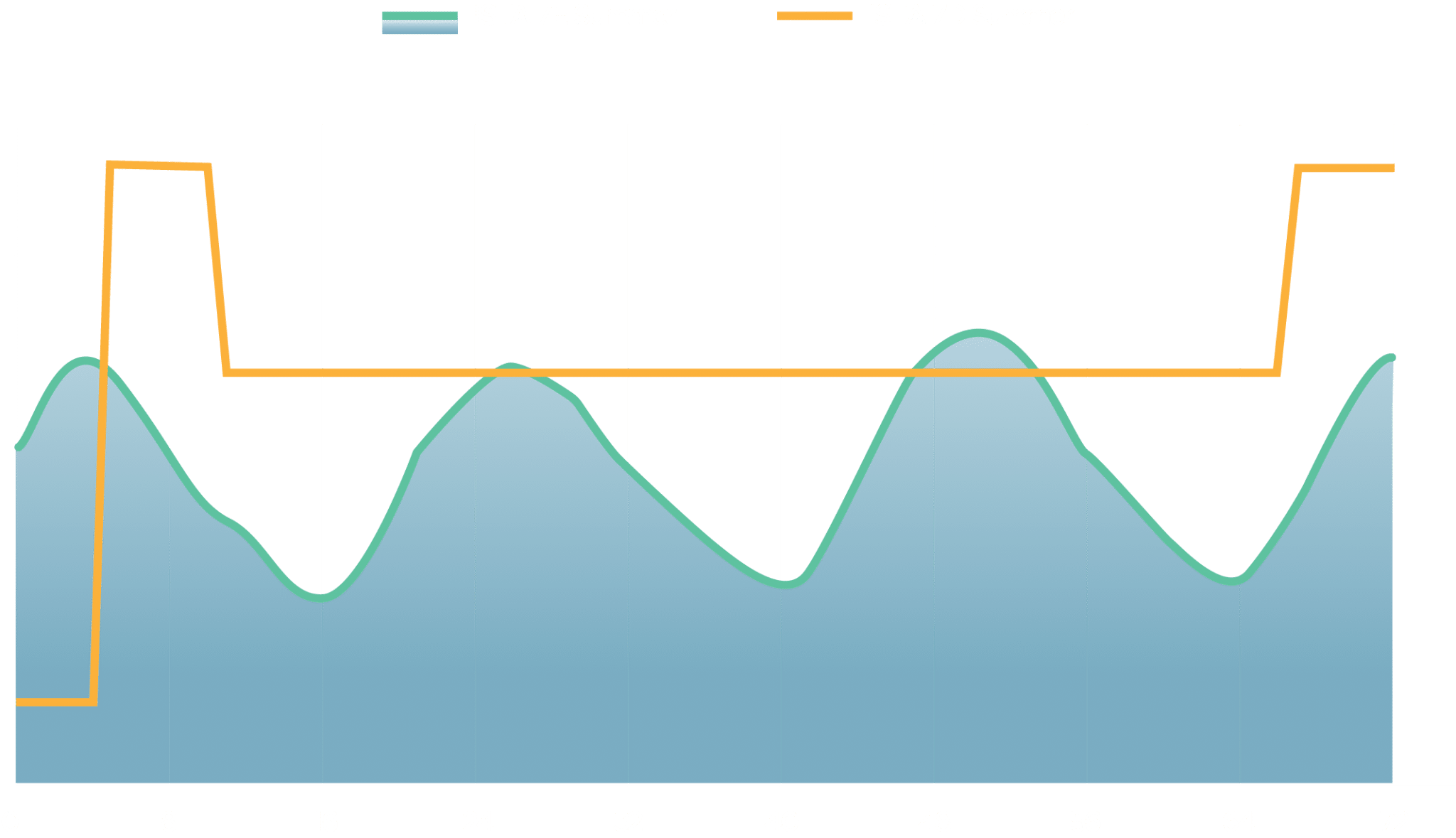

Recreating Real Life in a Thermal Chamber: ISTA 7E

Along with extensive guidance and requirements for the testing process, data collection, and documentation, Standard 20 also references the ISTA 7E thermal profiles for use in chamber testing. The ISTA 7E thermal profiles were developed through industry input to provide standardized methodology for the comparison of ISCs.

They include a standardized summer and winter profile that were built using an aggregation of data collected through an extensive study of shipping lanes spanning the United States. Each 7E profile contains up to 72 hours of data, which is repeatable for up to a total duration of 144 hours.

7E vs 7D

While the seasonal 7E profiles can be used to demonstrate performance for general domestic shipments, it may not reach the temperature extremes observed across specific regions. This is the reasoning for the PQ step in the Standard 20 process, but for many users a custom profile built using specific lane data may be more representative during chamber testing. Some end users address this discrepancy in temperature extremes by requiring ISTA 7D as the baseline for initial testing, with the intention of validating later down the road using real temperature data collected across specific temperature lanes to perform an OQ and following it up with a PQ.

A simple examination of 7E vs 7D will show the contrast between the two profiles. ISTA 7D was developed prior to 7E. It contains immediate temperature changes in the profile followed by hold/soak steps at a constant temperature, similar to what would be experienced when going from inside a warehouse to outside and vice versa. ISTA 7E was developed using an intensive data collection process, and generally represents the gradual temperature changes that can be experienced throughout the day.

Shake it Won’t Break It: ISTA 3A

The ISTA Standard 20 process also requires the ISTA 3A test, which is described as a “general simulation test for individual packaged-products shipped through a parcel delivery system”. The ISTA 3A involves a series of drops, dynamic compression sequences, and a loose load vibration portion that are meant to replicate the different forces that can be experienced by an ISC or other single shipment when sent through a service like UPS or FedEx.

Specialty Pharmacy:

When drug manufacturers and distributors make a submission to the FDA, both OQ and PQ documentation for an ISC are required to receive approval. However, specialty pharmacies that are subjected to URAC 4.0 requirements are only required to submit PQ data.

While not required by URAC, DQ and OQ testing is recommended to reduce the risk of failure during the PQ phase of the package development process.

Here to Help

When food or medicine requires temperature control distribution, the design and qualification of insulated shipping containers is an essential of new product development.

Through the ISTA Certified Thermal Lab at TemperPack, our team of engineers is able to carry out a standard or modified version of the ISTA Standard 20 process.

The Ellen MacArthur Foundation’s Upstream Innovation Guide Features ClimaCell®

The Ellen MacArthur Foundation has published its Upstream Innovation Guide. We’re thrilled that ClimaCell is included as a solution to replace plastic foam as a way to protect fresh food and other perishable shipments.

The circular economy is about changing the way we design and make products and packaging, so we can move from managing waste, to preventing it – benefiting businesses, their customers and the environment.

Plant-based insulation for perishable shipments, with comparable temperature control performance to expanded polystyrene foam (EPS), as well as being made from a renewable material and fully compatible with paper recycling streams.

Businesses around the world are starting to do this, but it is time to move at even greater speed and scale. We’re honored that ClimaCell was selected for the Upstream Innovation Guide, alongside incredible innovations from around the world. The guide is a valuable resource that includes new technologies and practical improvements companies are making to bring about a better future.

We’re honored that ClimaCell was chosen, alongside incredible innovations from around the world. The guide is a valuable resource that includes new technologies and practical improvements companies are making to bring about a better future.

About TemperPack

TemperPack® makes packaging that works for businesses, people, and the planet. The company was borne out of a desire to reduce the amount of unsustainable packaging caused by the rise of e-commerce and perishable delivery. Incorporating environmental responsibility into product design, the company specializes in bringing the highest quality packaging solutions to scale. Operating an ISTA® certified Thermal Transport Lab and state-of-the-art production facilities in Richmond, VA and Las Vegas, NV, TemperPack is rapidly expanding its reach in the perishable food and life sciences industries with recyclable and compostable packaging solutions. Our mission is simple: protect products with packaging that protects the planet.

About the Ellen MacArthur Foundation

The Ellen MacArthur Foundation is a UK-based charity, committed to the creation of a circular economy that tackles some of the biggest challenges of our time, such waste, pollution and climate change. In a circular economy nothing becomes waste and everything has value, creating benefits for society, the environment and theeconomy.

The Foundation collaborates with its Strategic Partners (BlackRock, Danone, DS Smith, Google, H&M Group, Intesa Sanpaolo, IKEA, Philips, Renault, SC Johnson, Solvay, Unilever, The Eric and Wendy Schmidt Fund for Strategic Innovation, SUN, MAVA, players of People’s Postcode Lottery (GB)) and its wider network of businesses; governments, institutions, and cities; universities; and emerging innovators, to drive collaboration, explore opportunities, and to develop circular business initiatives.

The current ‘take, make, waste’ extractive industrial model relies on the consumption of finite resources. The circular economy offers a positive way forward by redefining growth to focus on society-wide benefits. It entails redesigning material flows and production systems to build economic, natural and social capital. Underpinned by a transition to renewable energy sources, the circular economy is built on three principles: design out waste and pollution; keep products and materials in use; and regenerate natural capital.

Understanding Safe Temperature Ranges for Temperature-Controlled Shipments

From insulin treatments to meal kits, more temperature-sensitive shipments than ever are being shipped across the country to your door.

If those shipments get too hot (or too cold), they will lose potency or spoil and need to be discarded. These shipments require packaging materials designed to keep those items within their safe temperature range.

Understanding the safe temperature range for a product allows packaging engineers to design a custom pack-out with the right amount and arrangement of coolant and insulation to protect it.

Read on to learn more about the most common safe temperature ranges across life sciences and food.

Refrigerated

A common shipping temperature range is 2-8°C or 35.6-46.4°F.

Numerous vaccines and biologics are shipped in this range to extend shelf life and prevent damage to the active ingredients. Often these treatments include proteins, and refrigeration keeps them “alive.”

2-8°C is the most difficult shipping profile to maintain. Getting too cold or too hot will cause the treatments to lose potency. Freezing can cause proteins to break apart, and excess heat will harm them as well.

Some common medical treatments that require refrigeration are insulin, vaccines, Humira®, and some diagnostic tests.

CRT

The second most common temperature range for medicine is called “controlled room temperature” (CRT). 33% of all medicine shipped in the US and EU falls within this range.

Inside of the CRT, there are many different ranges of temperature control. However, most of them fall between 2°C (35.6°F) and 40°C (104°F).

When the life science industry is qualifying shipping solutions, the mean kinetic temperature (MKT) of the product is commonly used as part of the acceptance criteria. The MKT allows for temperature excursions while still maintaining drug efficacy.

Often treatments in this range take the form of solid pills, such as vitamins and acetaminophen. While these pills are stable across a broad temperature range, they aren’t impervious to harm from heat and cold. Freezing the pills or overheating them can cause them to explode (especially gels), melt, or lose potency.

Frozen

While many protein-based treatments cannot be frozen, many cellular treatments require frozen or even deep-frozen conditions in order to stabilize the formulation. When a treatment is frozen or deep frozen, it will be thawed and given to a patient within a very specific window of time when the treatment is activated.

Frozen is the broadest temperature range within cold chain shipments. Here are more details about the different classes of frozen treatments:

Depending on the product, less than or equal to -20°C (-4°F) is relatively common and includes API, or Active Pharmaceutical Ingredient, the starter material for many biologic formulations.

There are also certain life science products that require deep frozen temperatures, such as less than or equal to -85°C (-121°F). For example, plasma is one such product.

Finally, the coldest temperature range is less than or equal to -135°C (-211°F). This is known as a cryogenic and is typically used for cellular or gene therapies. The extremely cold temperatures will suspend activity in the cells to maintain integrity.

Food

Even though the food industry is not as regulated as much as the life science industry, the laws of thermodynamics still apply. Proteins can be spoiled by too much heat (and so can produce), and in some cases it’s possible to freeze items that aren’t meant to be frozen. Many of the same rules and temperature ranges from life sciences apply to food as well.

Most fresh meals and meal kit suppliers need to maintain a temperature less than or equal to 5°C (41°F). Interestingly, this temperature falls right in the middle of the most common life science range of 2-8°C. In addition to fresh produce, many types of proteins are also shipped with temperature control devices.

Below 0°C (32°F) is typical for frozen steaks, seafood, and plant-based proteins.

Desserts and specialty items can require different temperatures depending on the product.

Products like specialty cheesecakes can require temperatures below 0°C, while ice cream needs even colder temperature control by maintaining a temperature less than or equal to -17.8°C (0°F).

Keeping Shipments Safe at Any Temperature Range

Depending on the required temperature range and the duration of shipment, food and life science companies use either dry ice or gel packs as coolants, along with insulation. From a sustainability and business standpoint, the goal is to use enough coolant and insulation to ensure 100% protection of the shipment, but not use more coolant or packaging material than necessary. For a deeper look at the science of thermal shipment, check out this primer on cold chain shipments.

TemperPack

When it comes to maintaining specific temperatures during transit, it’s important to carefully consider your packaging options. At TemperPack, we manufacture and sell sustainable and cost-effective temperature-controlled packaging that will help ensure your shipments remain at their ideal temperatures. Contact us for more information.