Navigating Extended Producer Responsibility

Extended Producer Responsibility (EPR) is transforming how businesses manage packaging waste, shifting the responsibility from municipalities to the companies that produce it.

As more states and countries implement EPR laws, brands must adapt to new regulations, rising costs, and evolving consumer expectations.

Our free 11-page guide breaks down the current landscape, key challenges, and opportunities for businesses to stay ahead. Learn how EPR can drive sustainability, reduce waste, and create a competitive advantage.

TUV Austria OK Home Compost, UnPacked

Green Cell Foam™ is certified OK Home and OK Industrial by TUV Austria, the leading authority on compostable packaging. What does that mean? Here’s everything you need to know.

Who is TUV Austria?

TUV Austria is a global leader in providing industry best practices and certifications across safety, quality, innovation, and environmental protection, including product compostable certifications. TUV Austria’s clients, include leading enterprises and innovative companies across the globe, and countries such as France and Australia, base policies on TUV Austria’s guidelines.

Composting 101:

According to the EPA, composting is a “controlled, aerobic (oxygen-required) process that converts organic materials into a nutrient-rich, biologically-stable soil amendment or mulch through natural decomposition.”

A simpler definition: Composting is the natural process of recycling organic matter, such as leaves and food scraps, into a valuable fertilizer that can enrich soil and plants.

How does it happen? Microorganisms feed on the materials in a compost, using carbon and nitrogen to grow and reproduce, water to digest materials, and oxygen to breathe.

For composting can occur, three conditions are necessary:

- A balance of carbon-rich and nitrogen rich materials in a moist mixture.

- Oxygen-accessible environment.

- A high enough temperature to break down the materials.

What is the difference between ‘compostable’ and ‘biodegradable’?

According to the EPA, biodegradable means “ability of a substance to be broken down physically and/or chemically by microorganisms.”

When a product is biodegradable, it doesn’t necessarily enrich the soil or provide a foundation for new growth. All compostable products are biodegradable, but not everything that is biodegradable is compostable. Far from it. For a product to be compostable, it must biodegrade AND enrich the soil.

Home Composting vs Industrial Composting

Industrial Composting: Some materials, such as products or plastics made from starch, sugarcane, or agricultural waste, require temperatures nearing 55-60° Celsius to break down into compost. While not every US Metro area has easy access to industrial composting, many countries in Europe and Asia have well-established methods for collecting biowaste and creating compost in industrial sites. Products that can break down at the high temperatures achieved in an industrial composting site can earn the OK Industrial Compost label from TUV Austria.

Home Composting: Some materials can be broken down in garden composts, without industrial-level temperatures, such as vegetable or fruit scraps. Green Cell Foam is such a material, with vegetable starch as its principle ingredient. Green Cell Foam breaks down in garden composts and carries the OK Home Compost Label from TUV.

While access to industrial composting through municipal programs is growing, home compostable certified products enable and encourage backyard composting in rural areas.

How does a product obtain the certifications?

TUV Austria follows the European Norm for compostable packaging—EN 13432. Under those guidelines, there are four material makeup tests that must be passed to receive certification. The tests are the same for both OK Home and OK Industrial.

To pass, the material needs to:

-

- Be broken down on a chemical level—biodegradation

- Be broken down on a physical level—disintegration

- Not release toxins upon breaking down—ecotoxicity

- Have a low heavy metal content

To prove the characteristics above, products must pass 3rd party lab testing that meets protocols established by the American Society for Testing and Materials (ASTM), specifically ASTM D6400 and ASTM 6868.

D6400: Specific to industrial compost certifications, often pertains to plastics and products made from plastic designed to be compostable. It tests and compares the material’s biodegradability rate to known compostables.

D6868: Designed for a broader category of materials, products, and packaging that are meant for industrial composting. The product must break down physically, have inherent biodegradability, and must decompose without damaging its immediate ecosystem.

When Compostable Waste Goes to a Landfill

When compostable waste goes to a landfill, it gets buried under massive amounts of other trash, cutting off a regular supply of oxygen for the decomposers. The waste then ends up undergoing anaerobic decomposition, being broken down by organisms that can live without free-flowing oxygen. During anaerobic decomposition, biogas is created as a by-product. This biogas is roughly 50 percent methane and 50 percent carbon dioxide, both of which are potent greenhouse gases, with methane being 28 to 36 times more effective than CO2 at trapping heat in the atmosphere over a century.

Although most modern landfills have methane capture systems, these do not capture all of the gas; according to the EPA, landfills are the third-largest source of human-generated methane emissions in the United States.

Guess what? Most of the material in a landfill could be composted. According to the EPA, “in the U.S., food is the single most common material sent to landfills, comprising 24.1 percent of municipal solid waste. When yard trimmings, wood and paper/paperboard are added to food, these organic materials comprise 51.4 percent of municipal solid waste in landfills.” We see this as a huge opportunity to improve how we handle waste and to create a lot more compost.

Reach out.

If you’re looking to improve your customer experience, bolster packaging performance, reduce total costs, or move away from plastic, we’d love to talk.

Winning Pack-Outs for Winter

Many of our customers face a dilemma in winter: how do they reduce coolant and packaging costs, without going too far and creating a bad experience?

TemperPack has expanded and refined our product line to help customers thrive during winter. We offer thinner panels that outperform traditional plastic bubble and mylar that can be used without overhauling your pack-out.

ClimaCell

The leading curbside recyclable insulation for D2C shipments.

Green Cell Foam

The leading home compostable packaging insulation, available in stock sizes.

WaveKraft

New curbside recyclable insulation, produced near-site for flexibility and efficiency.

Need practical, lightweight insulation for winter? Need less plastic in your packout? We’re here to help. We’ve optimized our product line to give you options, and we’ve made it easy to switch. Contact us to get started.

Best Practices for Winter Pack-Outs

Get the Guide.

We’ve developed a guide of best practices for Winter practices, including product details, and pack-out examples. Check it out here.

2023 Impact Report

AT A GLANCE

More than a drop in the ocean, here are the key takeaways from the progress we made in 2023.

650+

Customers

In 2023, we helped protect over 650 companies fulfill their perishable shipments to millions of customers.

12K

Metric Tons Diverted

By choosing TemperPack products, our customers have diverted over 12,000 MT of single-use plastic packaging from landfills.

ESG Reporting

Onboarded ESG data management platform for higher grade carbon accounting.

34K

Metric Tons of CO2e

By choosing ClimaCell instead of EPS, our customers avoided the creation of over 34,000 MT of CO2e.

Full Report

Get the full report.

Fill out the form below to download our in-depth 2023 Impact Report.

Cytiva and TemperPack: Pioneering Biotech’s Sustainable Packaging Revolution

The Challenge

The primary challenge was to develop a packaging solution that not only matched the thermal insulation properties of EPS but also aligned with Cytiva’s sustainability goals. The packaging needed to ensure the safe transportation of temperature-sensitive products while significantly reducing the carbon footprint and enhancing recyclability of their shipments.

- Customer Quote -

When we said we wanted to find a replacement for EPS that could be used across our global network, a lot of people thought it couldn’t be done. TemperPack has been a great partner in working with us to launch a solution meets performance standards, achieves operational efficiencies, helps us reduce our CO2 impact and reduce non-recyclable waste at our customer facilities.

- Thibault Renaud

Sustainability Supply Chain Leader

The Solution

In pursuit of this goal, Cytiva sought out TemperPack, the leading provider of sustainable materials for cold chain. The team at TemperPack introduced Cytiva to ClimaCell, a curbside recyclable thermal insulation material designed to replace EPS.

This innovative material comprises thousands of tiny air pockets, effectively trapping heat and ensuring the maintenance of a safe temperature inside the box.

The Implementation

The implementation process was thorough and phased:

Product Validation

Cytiva rigorously tested ClimaCell to ensure it met their strict product and customer requirements. The testing included:

- ISTA (International Safe Transit Association) testing to simulate various environmental conditions.

- Pilot shipments across various sites with temperature loggers to monitor and ensure real-time shipment viability.

Operational Optimization

Unlike EPS coolers, ClimaCell’s solution can be shipped flat, offering significant savings in storage and transportation. This feature streamlined Cytiva’s logistical processes, reducing both physical footprint and shipping costs.

Customer Outreach & Education

Recognizing the importance of customer acceptance and education, Cytiva initiated outreach programs to inform their clients about the new packaging. This included sharing data on ClimaCell’s performance, recyclability, and the positive environmental impact of the switch.

Reduces carbon emissions by 30-40% compared to EPS boxes.

60K

Eliminate the use of approximately 60,000 polystyrene boxes annually, equivalent to around 71 shipping containers per year.

Enhanced customer satisfaction by ensuring product safety and demonstrating a commitment to environmental stewardship.

Realized operational efficiencies in storage and transportation due to ClimaCell’s flat delivery format.

Set a precedent in the biopharma industry, showcasing the feasibility and benefits of transitioning to sustainable packaging solutions.

Cytiva's journey with TemperPack, transitioning from EPS to ClimaCell, stands as a testament to what collaborative innovation can achieve in the realm of sustainable packaging.

By prioritizing environmental responsibility without compromising on quality and safety, Cytiva not only elevated its operational efficiency but also reaffirmed its commitment to a more sustainable future.

Caroline's Cakes and TemperPack: A Recipe for Sustainability

The Challenge

Caroline’s Cakes’ brand potential was being limited by its packaging.

Their team received consistent feedback from customers disappointed to see the cakes arrive in expanded polystyrene foam cooler (EPS, often known as Styrofoam®) and frustrated with the burden of disposing it. To address those concerns, meet the heightened expectations of fans around the country, and live up to their own values, the Caroline’s Cakes team looked to re-design their pack-out with better materials.

- Customer Quote -

Working with the TemperPack team has exceeded expectations at every opportunity. They approached our issue with care and concern for us as a customer and were active participants in troubleshooting our packaging wants and needs. Their hard work and attention to detail has helped us to transition to completely recyclable packaging without any disruption in our day-to-day operations. I value the relationship we have built and look forward to the next project that I can work on with their team.

Richard R. Reutter

President & CEO, Caroline’s Cakes

The Challenge

Caroline’s Cakes’ brand potential was being limited by its packaging.

Their team received consistent feedback from customers disappointed to see the cakes arrive in expanded polystyrene foam cooler (EPS, often known as Styrofoam®) and frustrated with the burden of disposing it. To address those concerns, meet the heightened expectations of fans around the country, and live up to their own values, the Caroline’s Cakes team looked to re-design their pack-out with better materials.

- Customer Quote -

Working with the TemperPack team has exceeded expectations at every opportunity. They approached our issue with care and concern for us as a customer and were active participants in troubleshooting our packaging wants and needs. Their hard work and attention to detail has helped us to transition to completely recyclable packaging without any disruption in our day-to-day operations. I value the relationship we have built and look forward to the next project that I can work on with their team.

Richard R. Reutter

President & CEO, Caroline’s Cakes

The Process

Discovery

Understanding Caroline Cake’s requirements, including fulfillment process, payload specs, shipping lanes, optimal temperature, and more.

Design

Developing pack-out designs to meet those needs. For Caroline’s Cakes, the engineers had to consider a few specific criteria:

Summer Heat

Caroline’s Cakes ships out of its Spartanburg, SC facility and has a large base of fans in the South. The shipper design had to stand up to summer conditions beyond ISTA-7E.

Air Flow in the Shipper

To protect the bottom of the cake and maintain consistent temperature throughout the box, TemperPack designed a corrugated tray to elevate the cake tin and create space for airflow.

Multiple Sizes & Payloads

The TemperPack team designed four shippers for various cakes, cake bites, BBQ, and seasonal items.

Design Criteria

Summer Heat

Caroline’s Cakes ships out of its Spartanburg, SC facility and has a large base of fans in the South. The shipper design had to stand up to summer conditions beyond ISTA-7E.

Air Flow in the Shipper

To protect the bottom of the cake and maintain consistent temperature throughout the box, TemperPack designed a corrugated tray to elevate the cake tin and create space for airflow.

Multiple Sizes & Payloads

The TemperPack team designed four shippers for various cakes, cake bites, BBQ, and seasonal items.

Qualification

Testing multiple samples of every design against Caroline’s preferred ambient profile, to ensure shippers would maintain frozen temperature during the summer.

The Results

Customer Review, October 2023

"5 Stars - Thanks for the great product, and the careful packaging and shipping!"

Customer Review, December 2023

"The care and attention to detail in packaging are as impressive as the cake! Thank you!"

100,000

LBS of EPS

By switching from EPS to ClimaCell, Caroline’s Cakes will help keep 100,000 pounds of EPS from going into landfills each year, a win for cake fans everywhere.

Thermal Shipping: The Basics of Cold Chain Shipping

Think of all the items that require you to have a refrigerator and freezer in your home – i.e., meat products, dairy products. These are just a few of the many perishable foods we use everyday that are temperature sensitive.

For example, milk must stay in the refrigerator or else it will spoil. But have you ever thought about how milk remains at a safe temperature from the time it’s produced until you purchase it at the market? Temperature sensitive products require thermal shipping solutions and in this case what is called a “cold chain” to remain safe and/or viable for consumption or use.

Part 1

What is Cold Chain Shipping?

The term “cold chain” is a broad term used to describe a temperature-controlled supply chain. The cold chain requirements (i.e., acceptable temperature ranges) of one product may look completely different from those of another.

Managing cold chain logistics has always been complex, and those complexities are continuing to evolve with the growth of the eCommerce industry.

Traditionally, cold chain products have been moved in high volumes to a small number of destinations. Revisiting the milk example, the cold chain for moving thousands of gallons of milk from a dairy farm to a grocery store might look like this:

Load up a reefer truck

(a 53’ trailer specially designed to maintain refrigerated temperatures within)

Drive it to the store

Unload the milk into a refrigerated warehouse

(where it will get loaded into the display cases as needed.)

With the direct to consumer industry booming, consumers now have the option to buy their milk online, perhaps from a boutique dairy farm multiple states away. As you’d imagine, the cold chain for this model looks vastly different from the cold chain of the “traditional” milk model.

Instead of shipping thousands of gallons of milk each of a few grocery stores, this boutique farm might be shipping a single gallon of milk to thousands of different addresses around the country. While the cold chain requirements stay constant in both models (milk still has the same safe temperature ranges), managing the cold chain for the latter model is a very modern challenge that businesses of today are working on overcoming.

These B2C (business to consumer) cold chains require specialty packaging and other packaging components to ensure that product integrity remains intact during transit. We’ll spend the rest of this article digging into the factors, science, and examples of the cold chain shipping industry.

Part 2

Cold Chain Shipping Factors

Now that you’re aware that the world of cold chains exists, it’s important to know the basic factors you should consider when analyzing a cold chain and making decisions that might influence your product’s safety, integrity or the overall customer experience.

When cold chain shipping is boiled down to the basics, the following factors arise as the driving ones:

Acceptable temperature range

Above all else, the “safe” temperature range for the item(s) being shipped must be identified and considered when making cold chain decisions. This range may seem obvious for some products (i.e., – ice cream should remain below 0°F/-20°C), but for specialty products, such as pharmaceuticals or cosmetics, manufacturers make sure any temperature requirements are clearly listed on the product’s primary packaging.

Time in transit

Once you know the temperature that a product must maintain, you need to consider how long the cold chain packaging needs to do its job.

A local grocer offering free delivery/shipping might only need packaging that maintains the appropriate cold chain for a few hours, whereas a large meal kit company might need to maintain a similar cold chain for multiple days as the boxes are traveling hundreds of miles through a courier shipping network.

Ambient temperature

The last factor to consider is what external “forces” the shipment will face during transit. The packaging protecting a shipment occurring in Texas in August will often look different than the packaging protecting a similar shipment in New York in October.

Part 3

User Requirement Specification

All three of the above factors combine to form the foundation of what is referred to in the industry as a User Requirement Specification (URS). Selecting the appropriate “requirements” for your packaging is a balancing act between cost and risk level.

Let’s say it’s the holiday season and you’re shipping a cosmetic product between New York and several customers within the Northeastern US with a 1 day transit time. The cosmetics have been proven stable between 0°C and 20°C.

You have the ability to set your URS to the level of risk you want to take when shipping your product. In an extremely conservative case, you can say that you want the packaging to maintain a product temperature between 5°C and 15°C for 3 days, regardless of the outside temperature (warm or cold).

This URS would prevent any courier delays or any abnormal temperatures for the season from harming the shipment, but would also result in unnecessarily expensive packaging to accommodate the conservative requirements.

A more cost-effective URS might require the product temperature to stay between 0°C and 20°C for 2 days in Winter temperatures. This wider temperature range and shorter duration will result in less expensive packaging, but will still give you reasonable risk mitigation to account for unexpected delays during shipment.

Part 4

The Science of Thermal Shipping

The three factors discussed above all come into play when considering the science that drives the cold chain shipping industry—thermodynamics, a sub-discipline of physics that essentially governs how heat (energy) is transferred.

Thermodynamics is governed by four laws, the second of which is most important for our discussion

Sparing you the technical nuances, the important morsels to acknowledge are that:

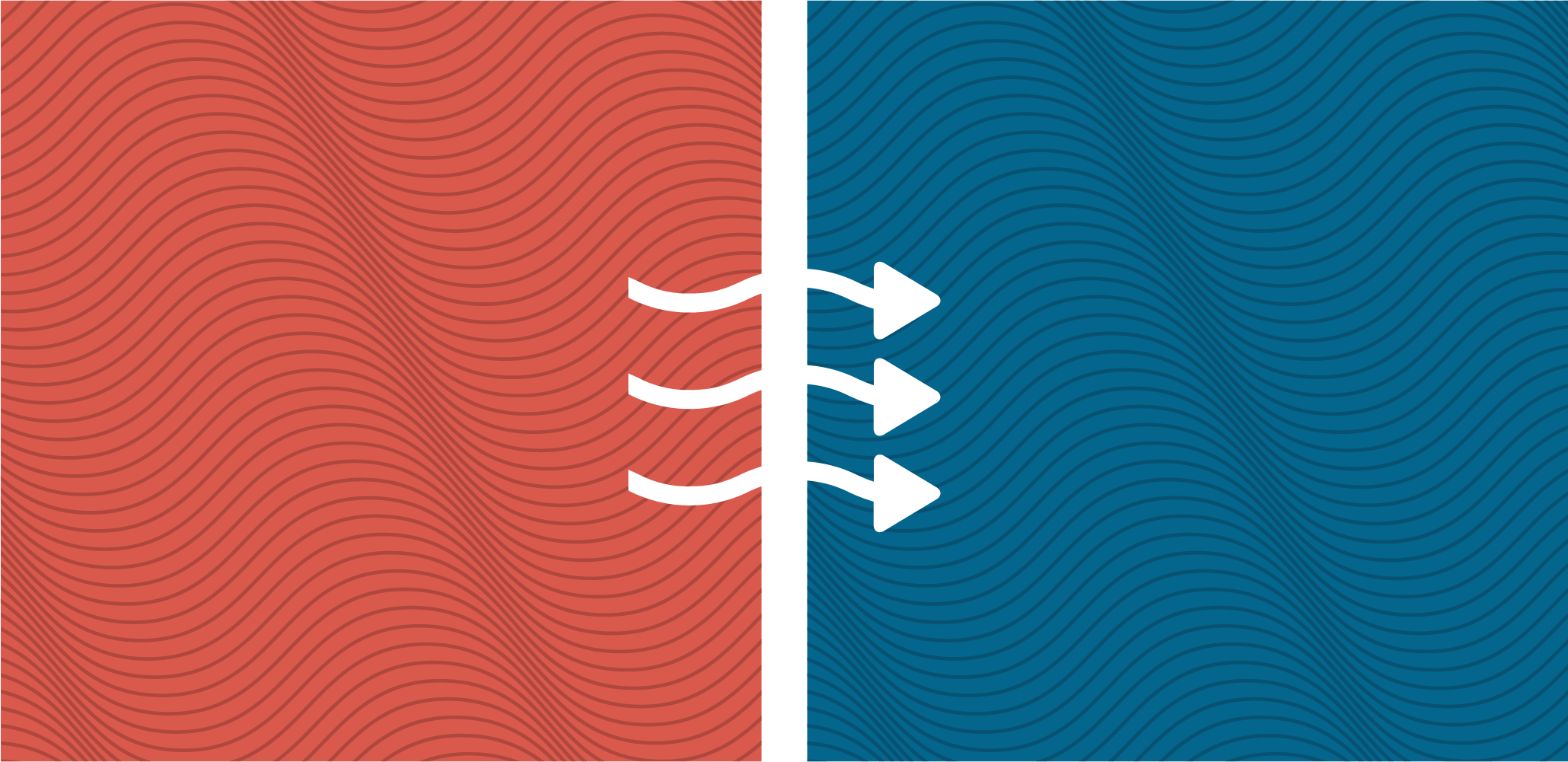

Heat flows from hot to cold

Heat will continue to flow until

an equilibrium (balance) is reached

The 2nd Law states that heat moves. But how? Hundreds of years of thermodynamics studies have codified the transfer of heat into three modes:

- Conduction – heat moves directly from one object to another via physical contact (i.e., melting butter in a pan on an electric cooktop)

- Convection – heat passes from one object to another via a fluid (i.e, – the fan in an oven moves air which transfers the heat from the heating element to the food in the oven)

- Radiation – heat is transferred by electromagnetic waves (i.e., – the sun heats the earth via electromagnetic waves that are transferred through space)

Because it’s the form of heat transfer most relevant to thermal insualtion, let’s take a deeper look at Conduction…

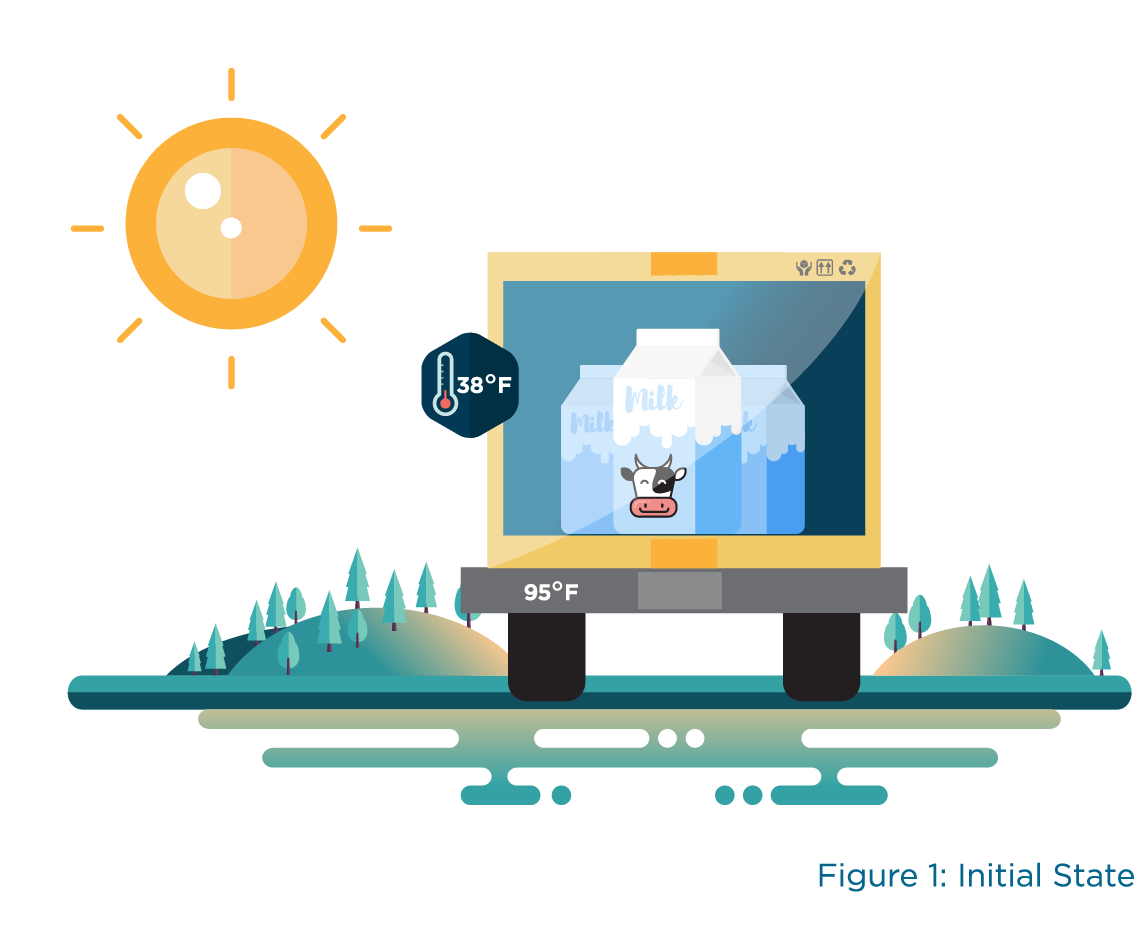

Let’s consider a cold chain shipping example where conduction is the primary mode of heat transfer. Figure 1, below, shows your gallon of milk freshly packed in an insulated box beginning its journey to the customer.

Since it’s summer weather, the bed of the truck is very hot.

As we learned from the 2nd Law of Thermodynamics, heat will flow from hot objects (the truck bed) towards cold objects (the milk) and will continue to flow until the temperatures reach an equilibrium (ie – both temperatures are equal).

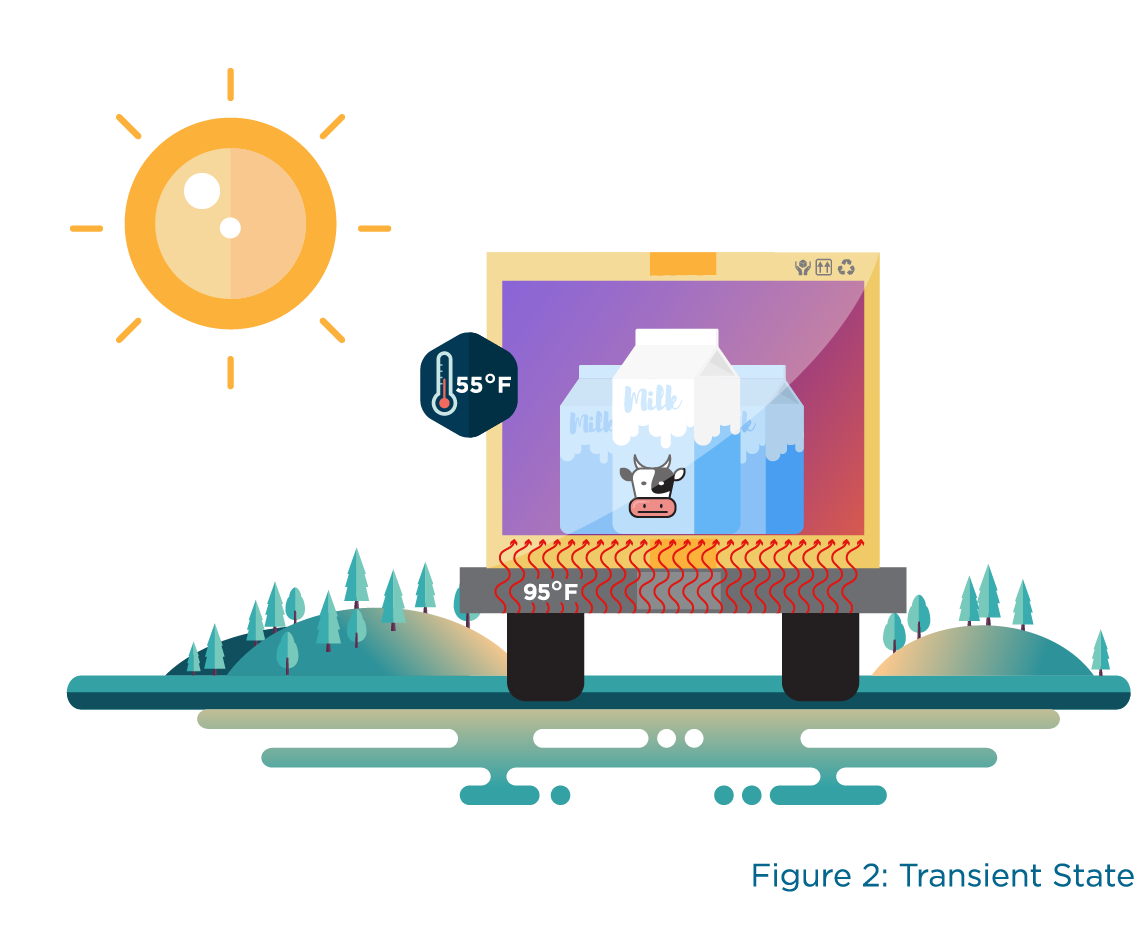

Figure 2, below, shows the heat being transferred into the box and gradually heating up the contents of the box.

Figure 3, below, shows the heat transfer ending because a thermal equilibrium across the box has been reached.

While this may seem like magic, scientists have distilled the transfer of heat via conduction down to this (simplified) equation:

Where:

- Q = Amount of heat transferred

- k = Thermal conductivity of the material transferring the heat. A highly conductive material will allow heat to flow through it very easily

- Thermal conductivity is an intrinsic material property of the insulation used to line the box

- FUN FACT: the inverse of thermal conductivity is thermal resistance (R-value!) and describes how good a material is at resisting the transfer of heat!

- A = area over which the heat is transferring

- The surface of the box in contact with the truck bed

- ΔT = difference in temperature across the material transferring heat

- 57 degrees (95 degrees – 38 degrees)

- x = thickness of the material transferring heat

- thickness of the insulation used to line the box

Part 5

More Cold Shipping Basics

Circling back to the basics, we know that heat is bad for your cold chain products, so you want to select packaging that will minimize the “Q” that is transferred from the ambient environment into the product being shipped.

Some of the variables in the heat transfer equation discussed above can be considered constants (or near constants) that you can’t tweak when managing your cold chain:

- ΔT – it’d sure be nice if you could control the weather, but since summer temperatures are always going to be hot and milk always has to stay refrigerated, you can’t simply minimize this variable to 0 and call it a day. Although that’s exactly what is happening when large dairy farms are shipping high volumes of milk directly to a grocery store! With the “outside” temperature also at refrigerated temperatures, there is no ΔT so no heat is flowing – it’s already in equilibrium.

- A – while you may have a little room to change your package’s size to reduce the area of the heat transfer as much as possible, you’re always going to be constrained by the size of the product you’re shipping so let’s consider this a constant as well.

That leaves you with two variables left for you to manipulate with your packaging decisions

- x – insulation thickness can be increased to slow down the amount of heat transferred into the product, but increases to insulation thickness often result in larger boxes (the extra “stuff” has to go somewhere and the product you’re shipping has a static size, remember?) so it’s not often an attractive option.

- k – this is where insulation makers make their money. Insulation with a low k-value (low conductivity), will not easily allow heat to conduct through it.

See? Cold chain shipping isn’t that bad. Once you identify your URS, you can apply those requirements to some basic thermodynamics equations and start making smarter decisions about your packaging.

We’re Here to Help.

Making the switch from traditional materials to sustainable and eco-friendly packaging is no longer a part of the distant future, but a current reality that companies must embrace to maintain a high ROI, nurture their stakeholder relevance and reduce their overall impact on our planet.

While it may not seem like an easy transition, sustainability in all aspects of your business begins with a commitment from you and all members of your company.

TemperPack Taps Renewable Energy Leader Peter Wells as Chief Executive Officer

TemperPack, the leading producer of sustainable materials for last mile cold chain shipping, has appointed Peter Wells as its new Chief Executive Officer.

Most recently, Peter served as CEO of Smart Wires, Inc, a leader in grid digitization and the acceleration of the adoption of renewable energy sources. Previously, Peter was CEO of General Electric’s Onshore Wind Energy division in Europe. Earlier in his career, Peter held leadership roles in nuclear and wind energy at GE, Vestas, and a range of start-ups and large corporations in the US and Europe.

Peter arrives at TemperPack during a time of expansion, with its acquisition of KTM Industries in late 2022 and the launch of its new WaveKraft platform earlier this year. The company has a workforce of over 700 employees in five facilities across the US. Its products are the leading alternatives to expanded polystyrene foam for perishable shipments, and its client roster includes leading food, pharmacy, and biotech companies.

“TemperPack’s a great company with a mission that matters. Its founders and leaders have built an organization committed to making a positive impact by meeting the needs of the market, with high performance, sustainable solutions. I’m thrilled for the opportunity to lead the company into its next chapter of growth.”

— Peter Wells, Chief Executive Officer

“Peter is the ideal person to lead TemperPack during this exciting time. We conducted a wide-ranging, extensive search, and after careful consideration, Peter rose to the top. He’s been successful leading startup, venture-backed companies and large public enterprises. He has great vision as well as the ability to roll up his sleeves in the day-to-day business,” said Jeff Possick, TemperPack Board Member and Managing Director, Goldman Sachs Asset & Wealth Management.

“Peter’s leadership, strategic acumen, and commitment to innovation match the culture and opportunity at TemperPack. He’s driven by a strong sense of purpose and has spent over 15 years leading companies in the sustainability space. He has a proven ability to bring people together to take on big, important challenges,” said Katrin Burt, TemperPack Board Member and Managing Partner at Grosvenor Food & AgTech.

About TemperPack

TemperPack’s mission is simple: protect products with materials that protect the planet. TemperPack was founded in 2015 to allow enterprises to ship perishable products without expanded polystyrene foam insulation (EPS, Styrofoam®) and other unnecessary plastic waste. Today, TemperPack is the largest producer of sustainable materials that protect temperature-sensitive shipments of food and life science products. Headquartered in Richmond, VA, the company develops and scales solutions that disrupt unsustainable packaging technologies and reduce the environmental impact of e-commerce. TemperPack’s products protect millions of shipments every month.

2022 Impact Report

In 2022, we expanded our solutions to displace single use plastic packaging, through:

Acquiring KTM Industries and their compostable Green Cell Foam

Launching WaveKraft, an on-demand, curbside recyclable, paper insulation system

But protecting the earth also means understanding our own impact, setting goals for reducing that impact, and sharing all that information with stakeholders. If you’ve made it to our website and are reading this, you’re a stakeholder. We welcome any feedback you have.

Our impact on the environment .

As a company dedicated to reducing the environmental burden of packaging, it matters to us that we know the impact of not only what we make, but how we make it.

Scope 1

814MT of CO2e

This number includes gas for trucks, natural gas, and propane used in our operations in 2022.

Scope 2

3,992MT of CO2e

This number includes purchased electricity used at all five facilities in 2022.

Scope 3

18,321MT of CO2e

This estimate comes from partial data from upstream and downstream activities, including raw material production, transportation, and disposal of our products. Emission calculations sourced from our LCA model built in SimaPro using EcoInvent and DATASMART databases. As our first year disclosing Scope 3, we expect this number to be more accurate next year, with the inclusion of employee travel and other material categories.

Intensity Factors by Product

| 2021 | 2022 | ||

|---|---|---|---|

| ClimaCell | |||

|

Scope 1 + 2 (KG CO2e per Kit) |

0.11 | 0.15 | |

| kWh per Kit | 0.31 | 0.30 | |

| Green Cell Foam (Q3/Q4 2022) | |||

|

Scope 1 + 2 (KG CO2e per Kit) |

- | 0.04 | |

| kWh per Kit | - | 0.07 | |

Intensity Factors by Facility

| Scope 1 | Scope 2 | ||

|---|---|---|---|

| ClimaCell (KG CO2e/kit) | |||

| Richmond, VA | 0.035 | 0.089 | |

| Las Vegas, NV | 0.006 | 0.179 | |

| Green Cell Foam (KG CO2e/board foot) | |||

| Holt, MI | 0.008 | 0.032 | |

| Reno, NV | 0.004 | 0.028 | |

Increasing efficiency within our facilities.

On the ClimaCell side of the business, we made some material changes in our manufacturing process in our Richmond facility in 2022, which led to a 8 percent decrease in kWh per kit used.

We also ramped up a second manufacturing line in Las Vegas, which accounts for the increase in per kit kWh out of that facility.

| Facility | 2021 | 2022 | % Change |

|---|---|---|---|

| Richmond, VA | 0.268 | 0.249 | -8% |

| Las Vegas, NV | 0.367 | 0.383 | 4% |

- Waste Diversion -

Cleaning House, One Step at a Time

By partnering with local material experts, we’ve diverted the following from ending up in landfills:

3,000 lbs

of food and organic waste from landfill by composting with NOPE

X lbs

of mixed paper, plastic, and metals by recycling with TFC Recycling

X lbs

of flexible plastic and hard to recycle materials through TerraCycle

In 2022, we protected over 30 million shipments of perishable goods with ClimaCell. By replacing their EPS insulation with ClimaCell, our customers avoided the creation of 40 million KG of CO2e.

That's the same as...

600K+

trees being planted and grown for 10 years.

+23%

increase over 2021

1.5MM+

light bulbs changed from incandescent to LED.

+18%

increase over 2021

8.6K+

cars taken off the road for an entire year.

+35%

increase over 2021

7K+

American home’s electricity use for an entire year.

+22%

increase over 2021

Our benchmarks on social responsibility.

“I found TemperPack when I was looking for a job with a company more aligned with my personal values. I was determined to find a company that was creating and facilitating change to help our planet.”

— Mollie Jarrett, Account Management, 4 years at TemperPack

Statistics

We're an ambitious company looking to do right by our employees.

71%

Response Rate to our Employee Engagement Survey

78%

Work Force “diversity” rate

Diverse is defined as traditionally under-represented groups across criteria including gender, race, or ethnicity.

33%

of our work force is female.

According to the US Census, women make up only 30% of manufacturing workforce across the United States. As an American manufacturing company, we are proud to have a higher-than-average proportion of women in our workforce and embed programs, such as the LADIES Network, to support our women in career and leadership development.

L.A.D.I.E.S Group

After establishing the Leadership and Development In Executing Success (L.A.D.I.E.S) in 2020, TemperPack has continued to invest and empower its workforce for all genders by partnering with Cascade Leadership Partners for career development coaching. The group plans to use this training to launch a peer-to-peer coaching program to problem-solve and strengthen cross-functional relationships as the company continues to grow.

MRF Visit

In November, our sales, product engineering, and sustainability teams visited our regional material recovery facility, TFC Recycling, in central Virginia. In addition to deepening our ongoing relationship with stakeholders who process our product at the end of its life, the visit yielded industry insights for our team to apply to sustainable packaging design and market growth.

Family Day

This fall, TemperPack hosted our inaugural Family Day at each facility in Virginia in Nevada to share our mission with family and friends. Volunteers hosted guided tours of our manufacturing plants, highlighting the history of our purpose and our commitment to innovation in both our products and our process.

Evaluating the governance of our business .

Our company’s commitment to maintaining ethical and responsible practices in all aspects of our operations, including our management structure, decision-making processes, and overall corporate governance.

- Governance -

In 2021, we partnered with Goldman Sachs Asset Management for an equity fundraising round. This strategic move enabled us to expand our operations and increase our market share while also gaining access to Goldman Sachs' expertise in building value across the enterprise, including best practices in ESG.

Materiality Topics

Identified 3 Material Topics: Climate Change, Product Excellence, and Manufacturing Efficiency that will shape our goals

ESG Committee

After establishing our ESG Committee in 2021, the group expanded to include the SVP of Sales, VP of Supply Chain, and CFO to oversee sustainability reporting, communication, and set goals for improving our impact.

ISO Certification

Our manufacturing facilities in Richmond, Virginia and Las Vegas, Nevada both feature ISO certification.

ISTA Certification

We maintained our ISTA certification in our Richmond testing and R&D facility, Proving Ground. With the KTM Industries acquisition, we've added a second testing facility to our portfolio in Holt, Michigan.

In 2022, our ISTA Certified lab was busy testing thermal performance of ClimaCell against incumbent insulation materials to curate custom pack outs for our customers.

663

Customer Pack-outs Tested

146

Custom Lab Reports Published

- Strategic Partnerships -

Lastly, we have purposefully surrounded ourselves with partners who help us stay informed and provide counsel when needed. In addition to our board, these include:

Clinton Global Initiative

In August 2022, we were asked to speak at the Clinton Global Initiative, an event that brings together those that are taking action on the world’s most pressing challenges. The event, put on by the Clinton Foundation focused on taking action together, and shed light on solutions like ClimaCell, helping eliminate the need for plastic-based insulating products.

Improving our impact in 2022

Product Composition

Reduced the thickness of LDPE coating of our outer paper by 50% and increased the usable fiber in our outer paper, making it more valuable to MRFs and paper mills.

Silo Project

Reducing trucks, reducing carbon in upstream activity, increasing efficiency and air quality of manufacturing plant.

WaveKraft

Launched WaveKraft, paper-based thermal insulation that reduces truck deliveries by 10x.

Our goals for 2023.

We think the best packaging solutions are one’s that use the least amount of material necessary, require the smallest amount of energy to produce, and can be produced, stored, and disposed of as efficiently as possible. With that in mind, here are our goals for 2023.

Build a Green Cell Foam vs. EPS comparative LCA model and submit it for panel for review to understand the product’s environmental impact.

Develop a more robust methodology for calculating Scope 3 emissions for our top material categories.

Reduce safety TRIR incidents by 25% for 2023.

Complete audit of supply chain to bolster transparency, mitigate risks, and find opportunities for greater efficiencies and improved environmental impacts.

Develop baseline impact metrics for our new WaveKraft product line.

Why we built WaveKraft.

A really good idea will tend to haunt you.

At TemperPack, discovering those ideas is our job. The Nobel prize-winning Hungarian scientist Albert Szent-Györgyi once stated that, “Discovery is simply seeing what everyone else has seen – but thinking what no-one else has thought.”

In 2015, upstart meal-kit companies were faced with a major packaging problem. They needed to figure out how to send millions of boxes of fresh food to houses across the country each week – without using Styrofoam coolers to keep items cold.

This is when (and why) we started TemperPack.

Our first discovery was jute – a natural fiber grown in South Asia but cheaply available in the US in the form of discarded burlap bags used for coffee and cacao imports. We also discovered that bedding and felt companies in the US had available capacity due to the rising popularity of foam mattresses. We connected the dots and started making thin, compostable insulation blankets from 100% recycled jute fibers. We pitched this as a new type of packaging that was highly insulating, flexible, plant-based, cushioning – and available at a low cost. The idea caught on and from 2015 to 2018, TemperPack manufactured and sold tens of millions of pounds of plant fiber packaging insulation. During this time, we also developed and commercialized PopBox, which allowed customers to replace millions of non-recyclable bubble foil liners with a fully recyclable, paper-based box liners.

We were in business...

but we weren’t totally comfortable (and I hope we never are).

We constantly asked our customers to imagine better versions of our products. What would it look like? What would it allow them to do more effectively? They told us that a better version of our plant fiber insulation would be compatible with the paper recycling stream, and that it would be lighter, faster to pack, and more rigid. They said a better version of our product would have tighter tolerances, a more consistent fit, and a wider performance range. It should be cheaper, and it should also be available in even larger volumes. It should be natural, but not “too natural” – no dust or noticeable smell. Clean & consistent. And they wanted it nationwide.

So we went out to discover. After inventing and discarding several novel material concepts – we noticed that food snacks (like Cheetos, made from puffed corn) were lightweight, cheap, renewable and had surprisingly good insulating qualities due to their foam structure. They were water soluble. They also could be made anywhere and, being made of starch, possessed a natural adhesive quality. We invented insulation panels that combined paper with puffed corn starch to line the walls of a cardboard box. We named the new product “ClimaCell”. Today, ClimaCell (along with our Green Cell Foam product line) is being produced across the country, protecting millions of food shipments each week.

But we're still not satisfied with our products...

and will never be.

About 18 months ago, we again asked our customers to imagine a better version of packaging. Again – what would it look like? What would it allow them to do more effectively? This time, they didn’t describe a “faster horse”. They told us about the burden of receiving multiple truckloads a day of packaging insulation, and the pain of storage and inventory management. They told us about the challenge of multi-week lead times. In short, they didn’t tell us about a better version of packaging insulation, they lamented the fact that packaging insulation was necessary to begin with. This was key because, as Peter Drucker says, “Nothing is less productive than to make more efficient what should not be done at all”.

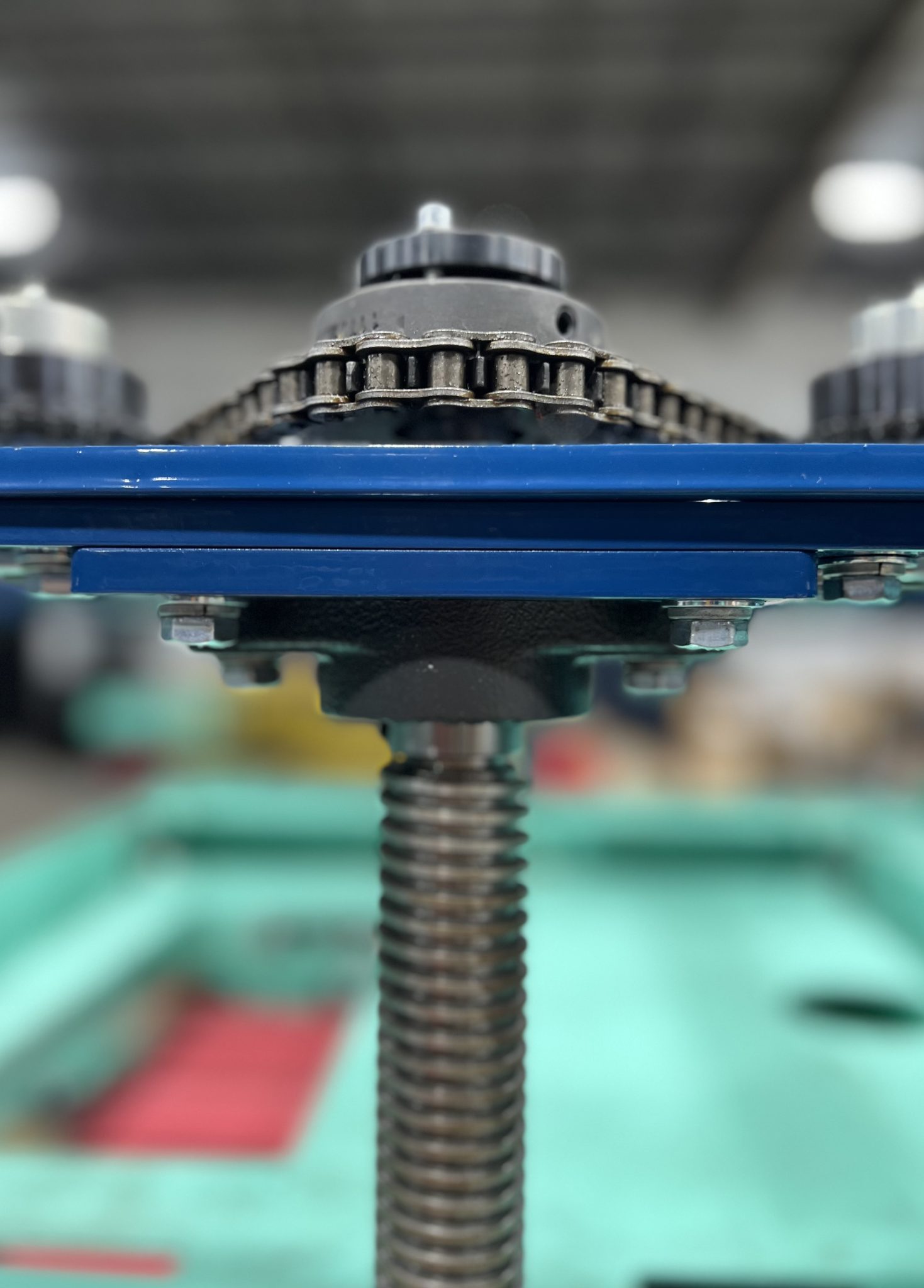

This is why we invented WaveKraft. It makes storage in a fulfillment center disappear.

WaveKraft is made from paper and is easily recycled with the cardboard box that consumers get each week. WaveKraft is also made on a machine that is 99% smaller than a traditional manufacturing operation – meaning that customers can put a machine right on their floor. Using WaveKraft for a year, customers can avoid over 1,000 inbound trucks and reclaim 80% of the storage space that they currently use for packaging insulation. We’re excited to offer a solution that is not only cheaper, but far more versatile and easier to use than what’s available on the market today.

Had you told me in 2015 that we would have a team of 600+ spread across 4 manufacturing sites producing millions of sustainable packaging products each week I might not have believed you. But I’ve learned that growth happens when you relentlessly do what you feel you are unqualified to do. We’re excited to launch WaveKraft – and we’re excited to make it better. Our customers will always be the foundation of our drive to invent. Whatever we do, it’ll never be good enough – and that’s why I love going to work.

- James McGoff

Chief Product Officer

& Co-founder

TemperPack

WaveKraft

Our latest invention.

Designed for operations. Sustainable by design.

We believe the best packaging solution is one that uses the smallest amount of necessary material, can be stored as efficiently as possible, and can be easily recycled. We have always set these guiding principles when we develop new products, and WaveKraft is no different. If you’re ready to revolutionize your fulfillment operation, let’s talk.